Elevating Antenna Performance in Handheld Devices through Precision Heat Staking

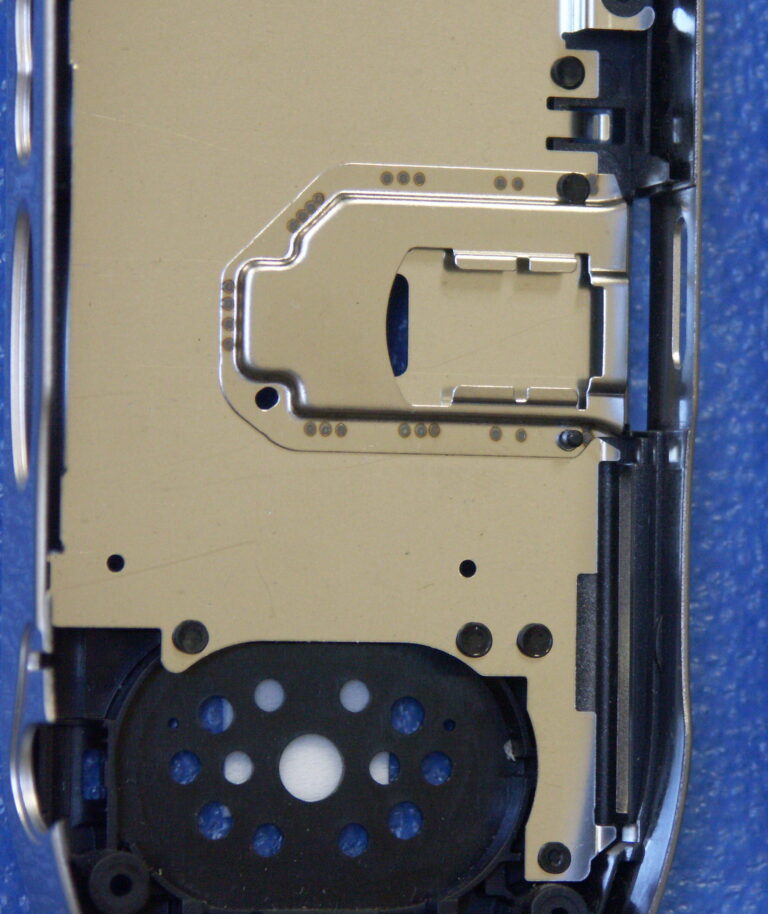

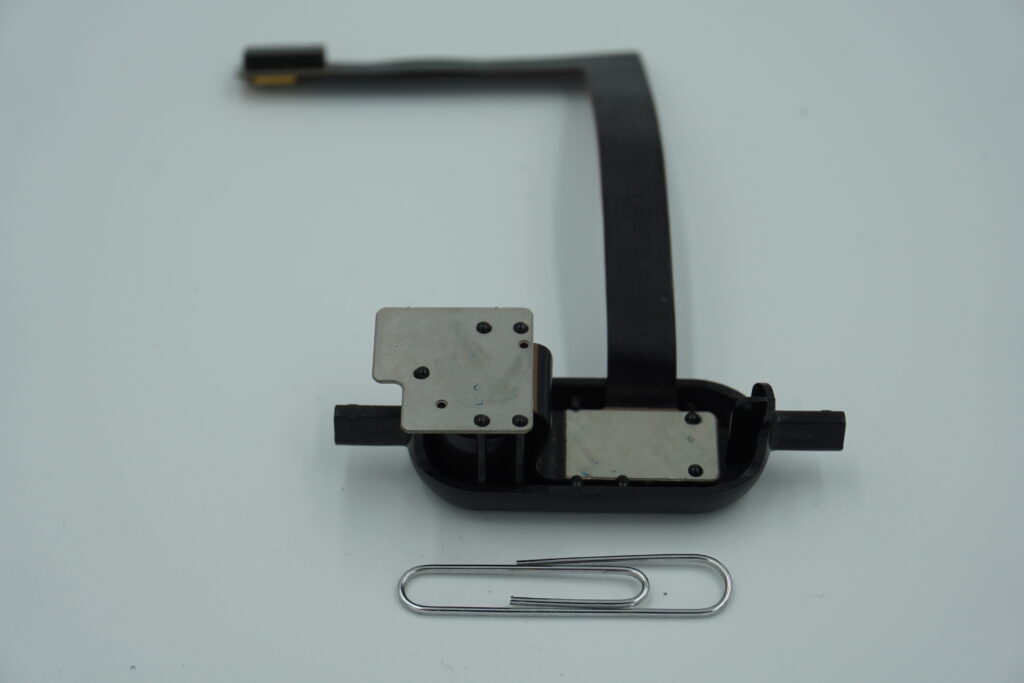

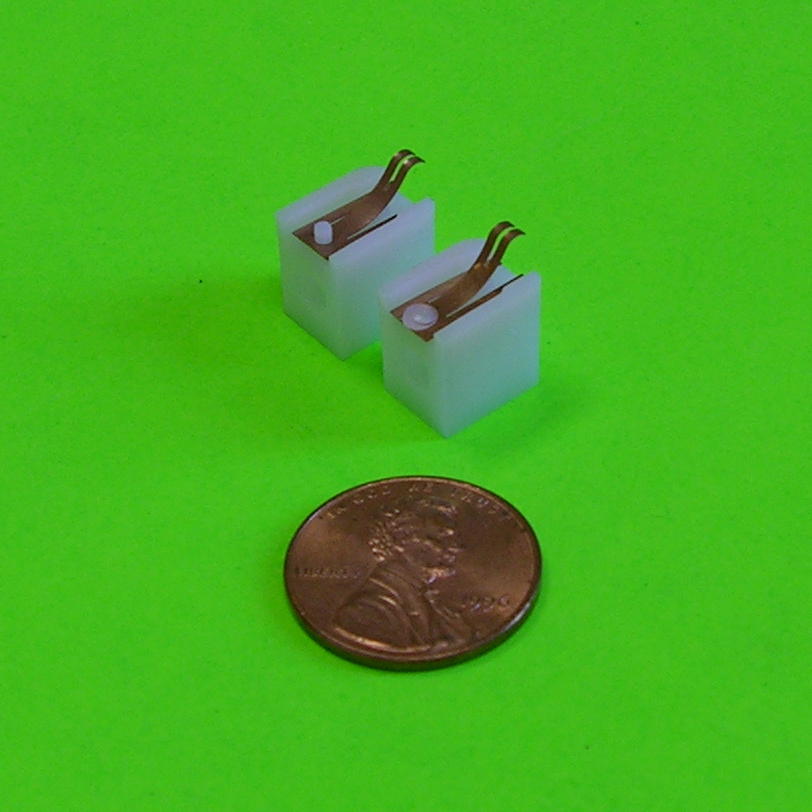

As electronic devices continue to shrink in size, the demand for efficient use of space within their enclosures becomes ever more critical. In the realm

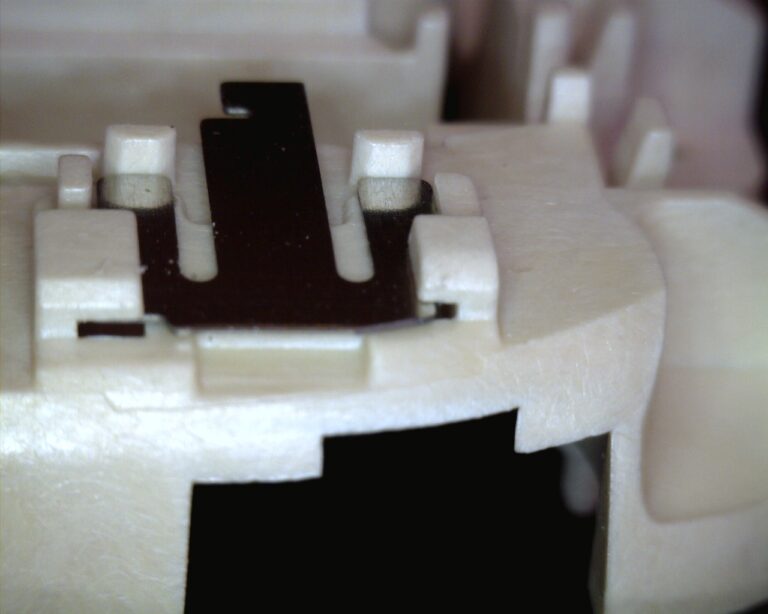

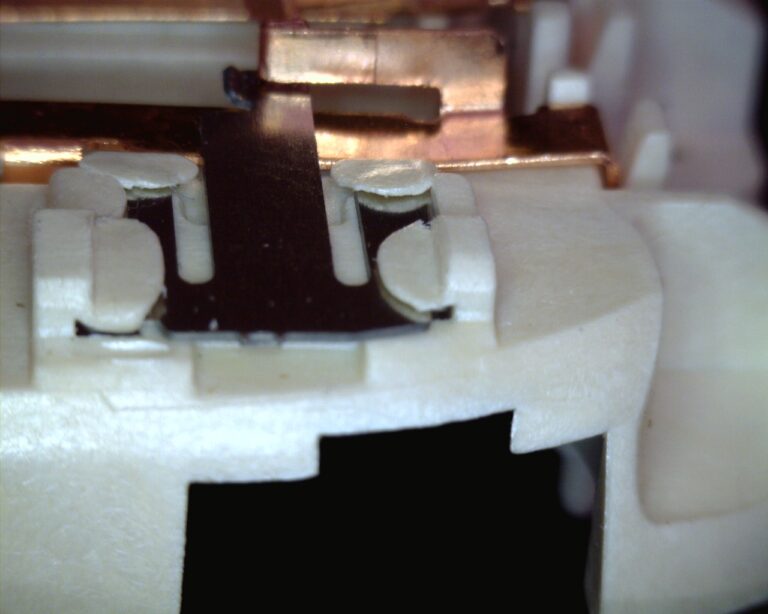

Heat staking is a widely used and effective method for attaching metal components to plastic. Its ability to create strong, durable, and reliable bonds makes it a preferred choice in industries such as automotive, consumer electronics, medical devices, and household appliances. By leveraging the benefits of heat staking, manufacturers can achieve precise, cost-effective, and clean assemblies, ensuring the quality and performance of their products.

As electronic devices continue to shrink in size, the demand for efficient use of space within their enclosures becomes ever more critical. In the realm

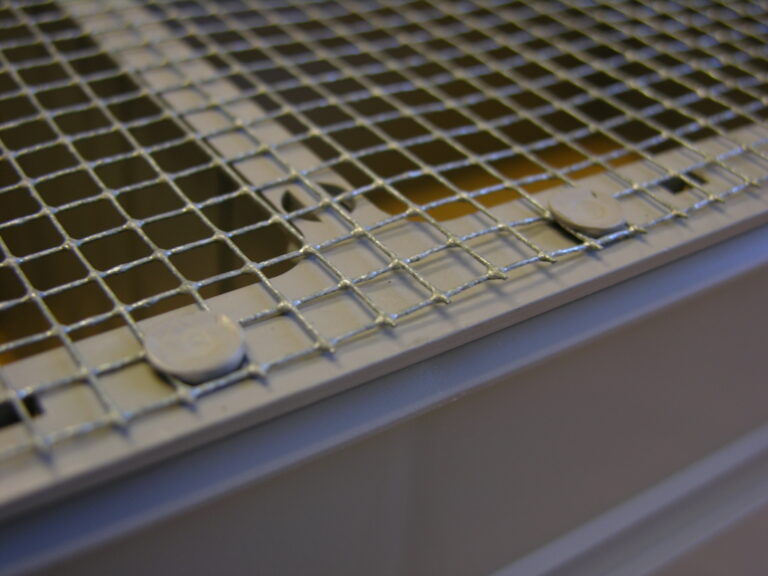

Traditionally, attaching metal grilles and screens to plastic frames has involved the use of additional fasteners, including screws, clips, rivets, or adhesives. However, these methods

In the dynamic realm of automotive innovation, one aspect stands out: the evolution of LED technology. As a frontrunner in precision heat staking machinery, Thermal

This video showcases a specially customized H-Series machine, equipped with four distinct thermal heads for optimized versatility. It also features a power shuttle table for enhanced efficiency. To ensure operator safety, the machine is designed with dual-hand Opto button controls, requiring both hands to be engaged before initiating each cycle.

This video showcases a custom-format Thermal Press machine engineered to heat stake a large automobile taillight assembly. The system features a multi-actuator setup and multiple thermal heads, ensuring precise and efficient processing of this complex component.

This video showcases our H-Series machine, used to heat stake the bezel of an automobile dashboard in a 2-up format. The system features a customized nest and clamping mechanism to ensure precise and consistent bezel placement on every run. It also includes a power shuttle table for smooth and efficient loading and unloading.

This video showcases our C-Series machine, designed to heat stake an iron faceplate for a card reader. The setup includes a power shuttle table, providing efficient and easy loading and unloading of the part for streamlined operation.