Enhancing Plastic Housings: The Art of Thermal Insertion for Threaded Inserts

Introduction: In the realm of product design, the choice of materials often plays a critical role in determining the functionality and longevity of a product.

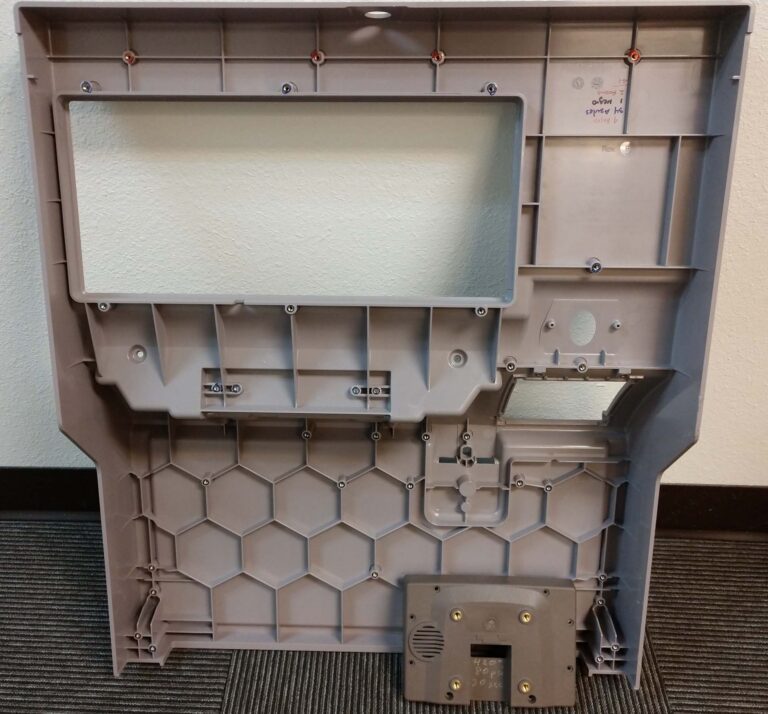

Heat staking is an effective method for the thermal insertion of threaded inserts into thermoplastic materials. By using controlled heat and pressure, it creates a strong bond between the insert and the plastic, ensuring reliable and durable threaded connections. This method of thermal insertion is widely used in various industries for its precision, consistency, and ability to handle different types of inserts and materials. Unlike competing methods, such as ultrasonics, thermal technology can simultaneously stake multiple inserts on various planes. This capability makes thermal not only a faster option but also a more economical choice.

Introduction: In the realm of product design, the choice of materials often plays a critical role in determining the functionality and longevity of a product.

This video showcases a C-Series Thermal Press equipped with a power shuttle table, facilitating easy loading and unloading of parts. After the threaded inserts are loaded, safety protocols require both hands to engage the Opto buttons to initiate the heat staking process. Custom-designed heat stake probes and a corresponding fixture ensure precise and consistent results on every run.

This video showcases our C-Series machine being used to heat stake threaded inserts. The system features a customized nesting setup to ensure precise positioning of the parts on every run. It also utilizes a rotary table for efficient loading and unloading, providing increased production capacity.