The Essential Role of Heat Sealing Foils and Film in Manufacturing Various Medical Diagnostics

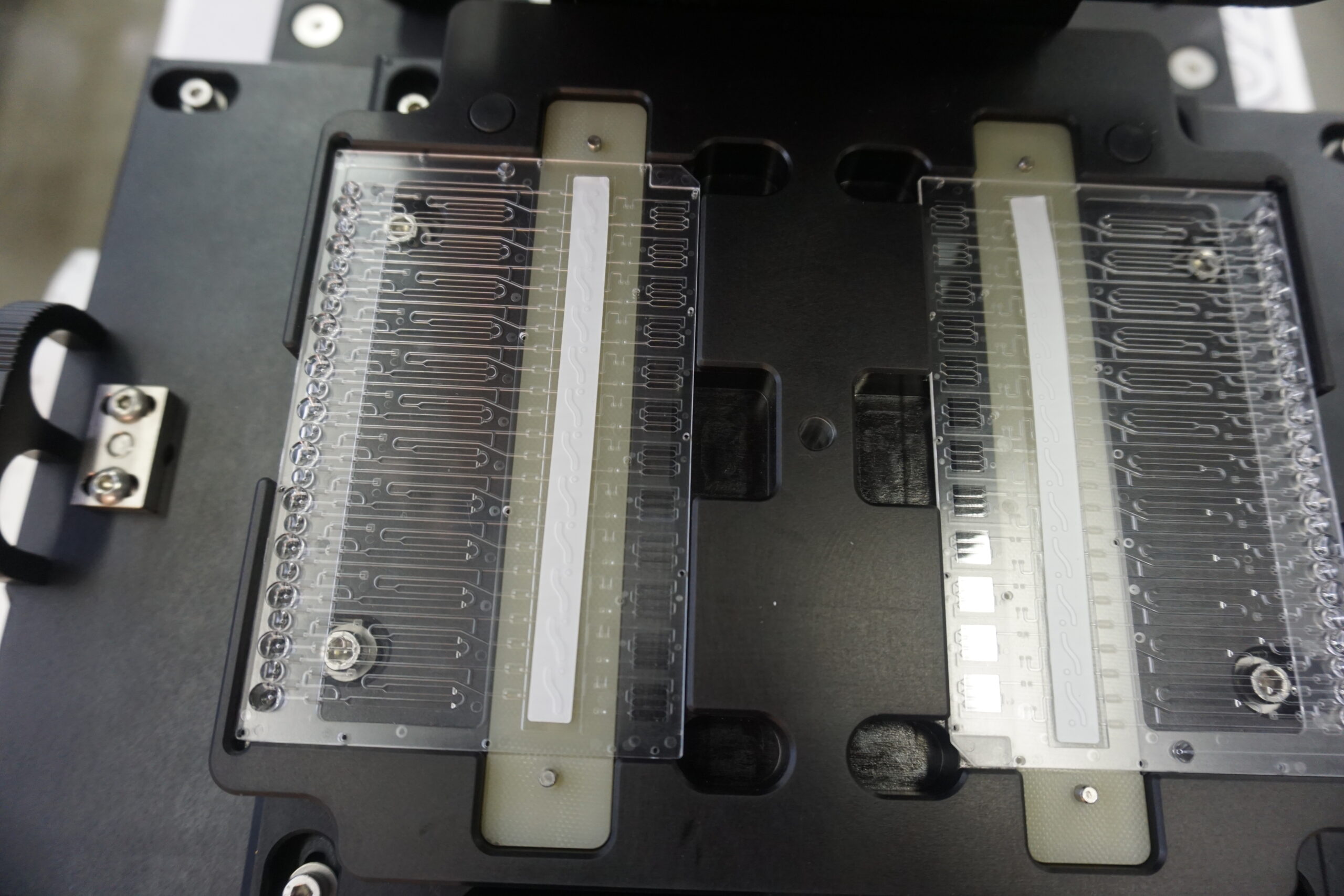

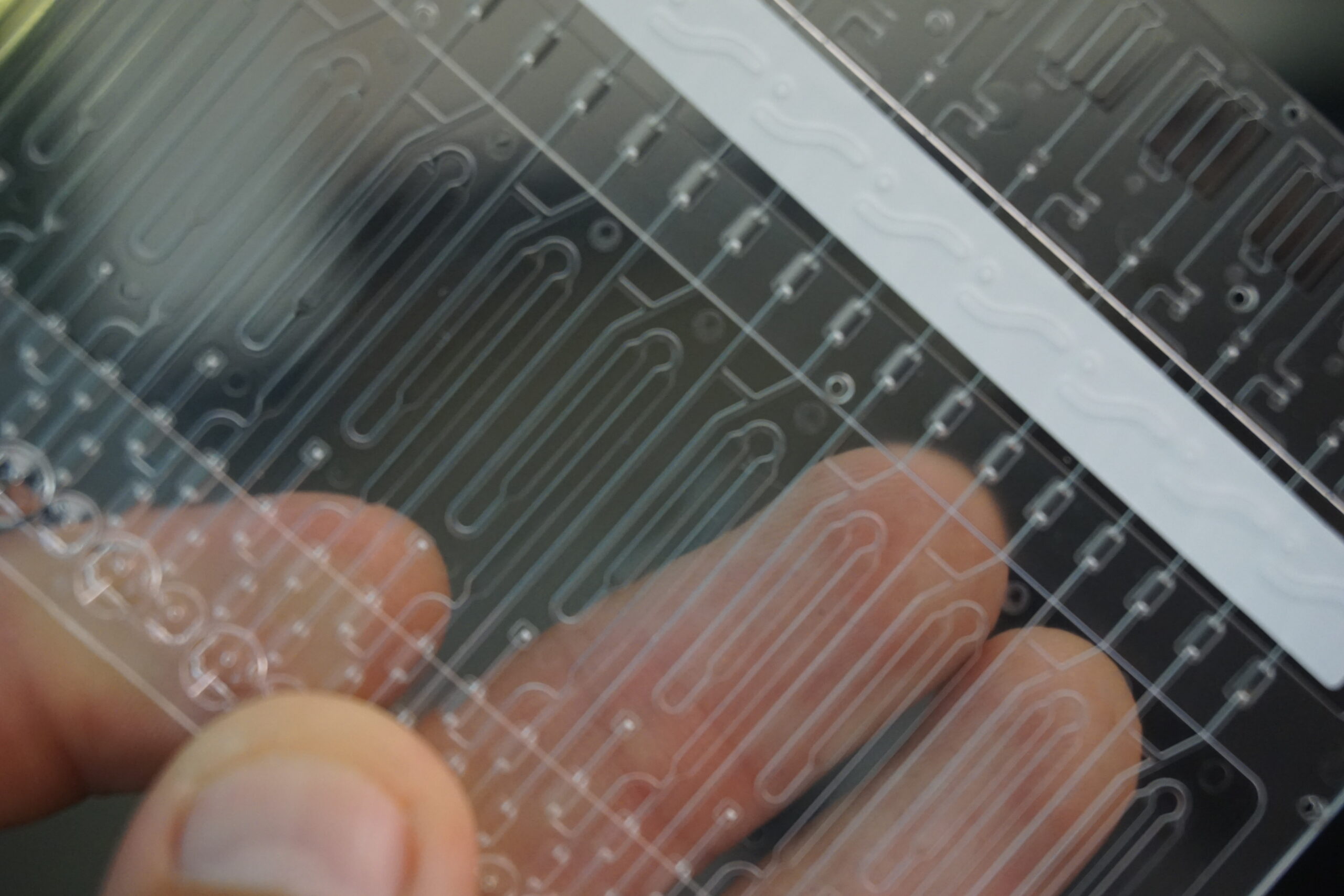

In the rapidly advancing field of medical diagnostics, the demand for reliable, high-quality products is greater than ever. A critical process that underpins the manufacturing