The Strategic Importance of Heat Staking in PCBA Manufacturing

In the electronics manufacturing landscape, Printed Circuit Board Assemblies (PCBAs) form the backbone of virtually every modern device. With the push toward more compact, efficient,

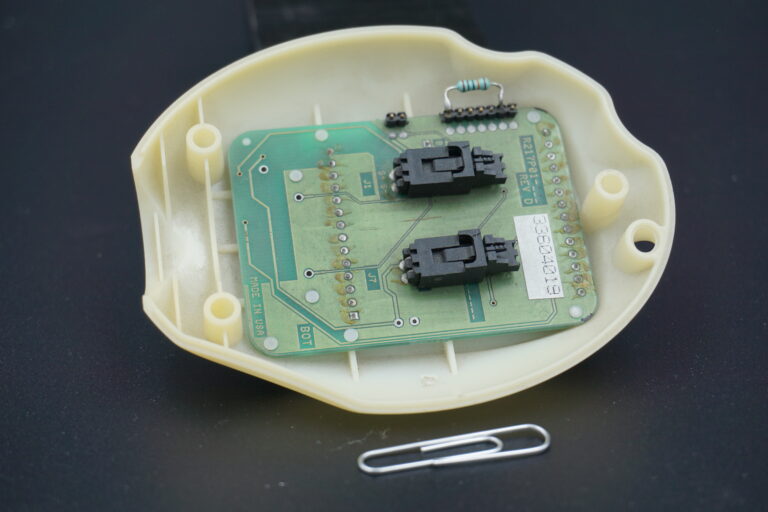

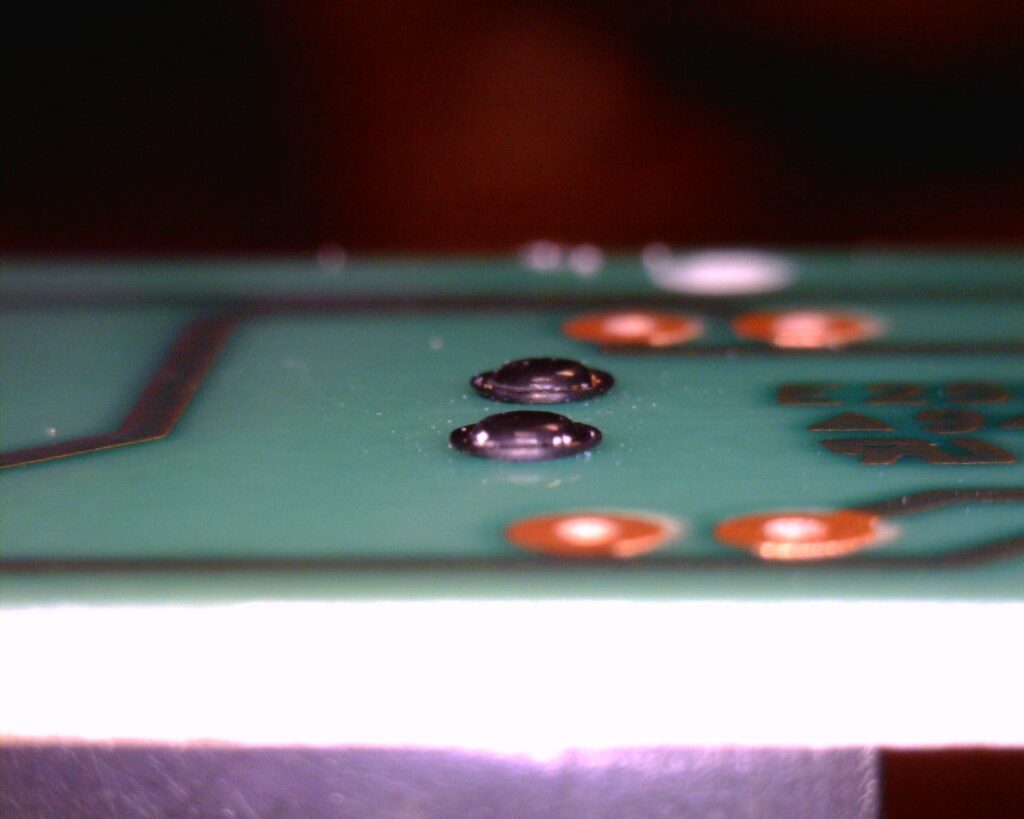

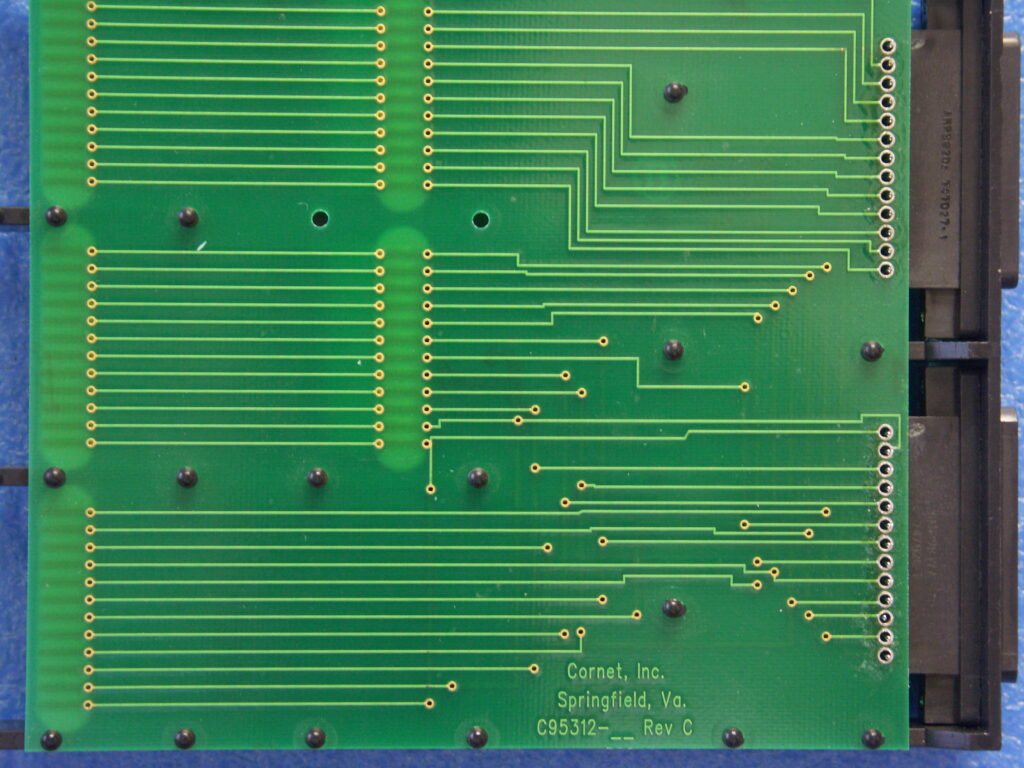

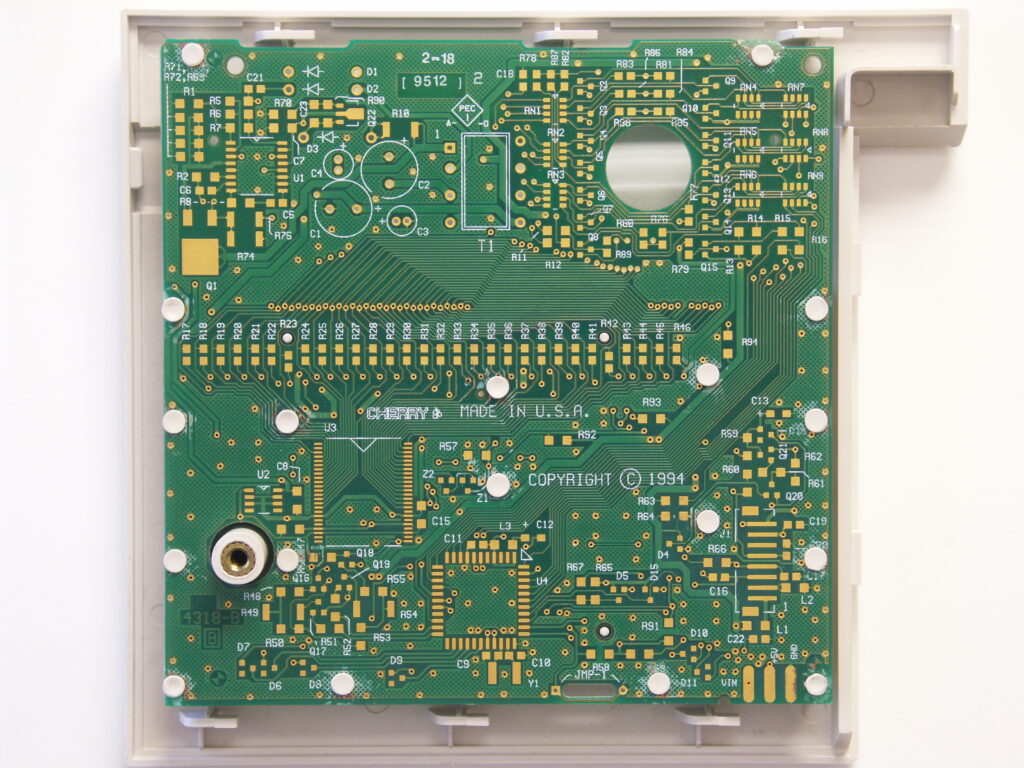

Heat staking is commonly used to attach plastic components to PCBs and for securing PCBs within housings. Its advantages include strong mechanical bonds, cost-effectiveness, and efficiency, making it a popular choice in the manufacturing of electronic devices as well as automotive and medical electronics. By providing a reliable and durable connection, heat staking helps ensure the longevity and performance of PCB assemblies.

In the electronics manufacturing landscape, Printed Circuit Board Assemblies (PCBAs) form the backbone of virtually every modern device. With the push toward more compact, efficient,

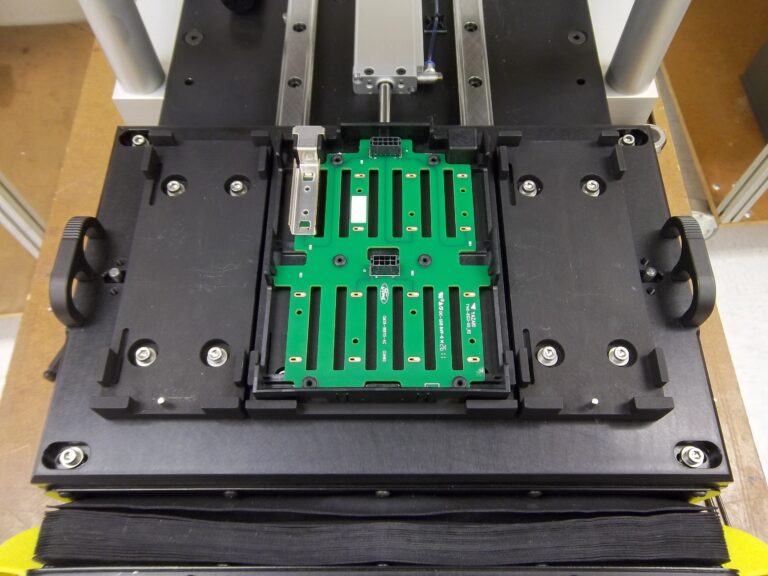

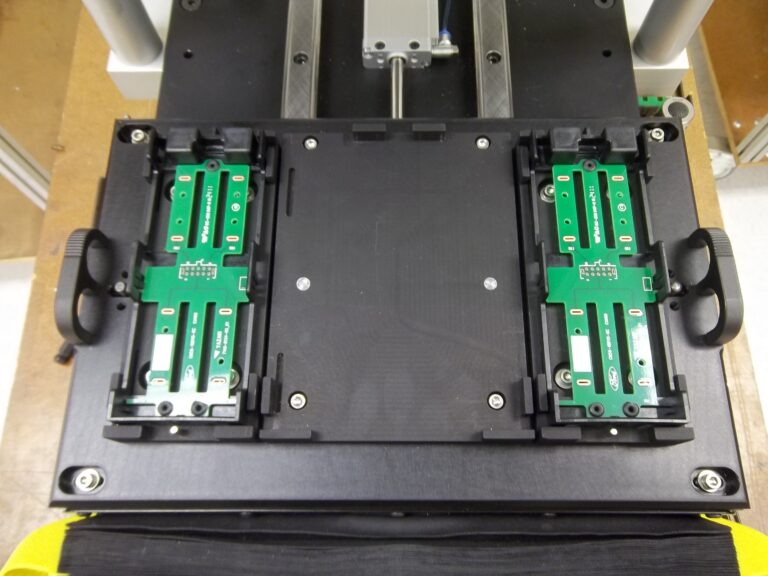

This video showcases our C-Series machine, featuring a specialized nest designed for heat staking two small PCBs simultaneously. For streamlined operation, the machine is equipped with a power shuttle table, allowing for easy and efficient loading and unloading.

This video showcases a C-Series machine equipped with a rotary table for efficient loading and unloading, along with increased production capacity. The system also features custom safety guarding and a light curtain to ensure operator safety during operation.

This video showcases a C-Series machine equipped with a larger rotary table for efficient loading and unloading, designed to boost production capacity. It features customized nesting to ensure precise placement on every run. The system is also equipped with custom safety guarding and a light curtain, ensuring optimal operator safety throughout the operation.

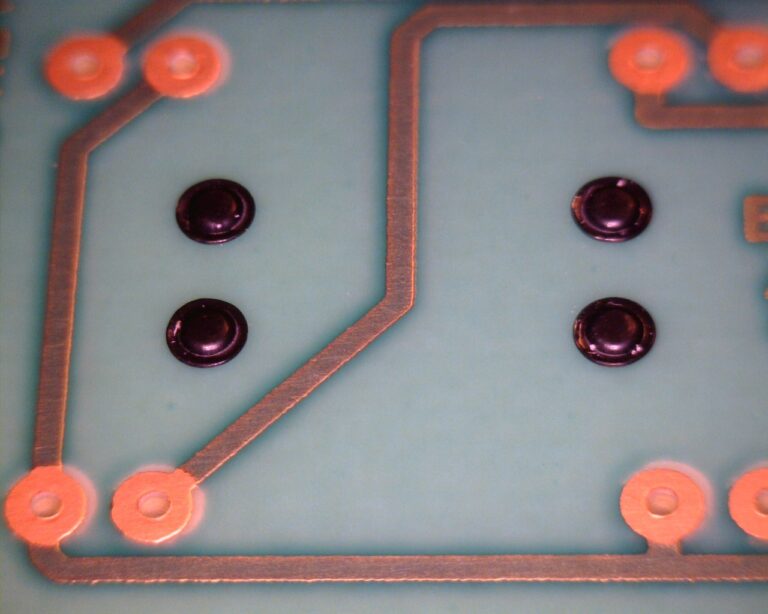

This video features an up close view of an H-Series machine heat staking a PCB with multiple heat stake posts.