Why are Plastics Hard to Glue?

Plastics are widely used in modern product designs due to their versatility, low cost, and superior performance characteristics. Compounds like acetals, polypropylenes, and polyethylenes offer

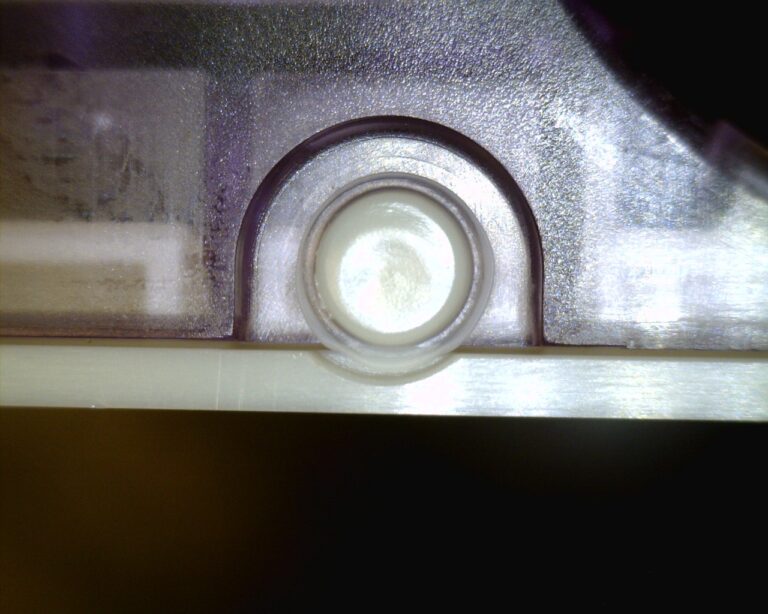

Heat staking is a widely used method for attaching dissimilar plastic parts in manufacturing due to its ability to create strong, durable bonds with precision and consistency. Its compatibility with various thermoplastics, cost-effectiveness, and clean process makes it an ideal choice for high-volume products across multiple industries, including automotive, consumer electronics, medical devices, and household appliances.

Examples of Parts

Plastics are widely used in modern product designs due to their versatility, low cost, and superior performance characteristics. Compounds like acetals, polypropylenes, and polyethylenes offer

At Thermal Press International (TPI), we often advise customers on optimizing their plastic parts assembly and manufacturing processes. When joining plastic parts to form a

This video showcases our H-Series machine, used to heat stake the bezel of an automobile dashboard in a 2-up format. The system features a customized nest and clamping mechanism to ensure precise and consistent bezel placement on every run. It also includes a power shuttle table for smooth and efficient loading and unloading.

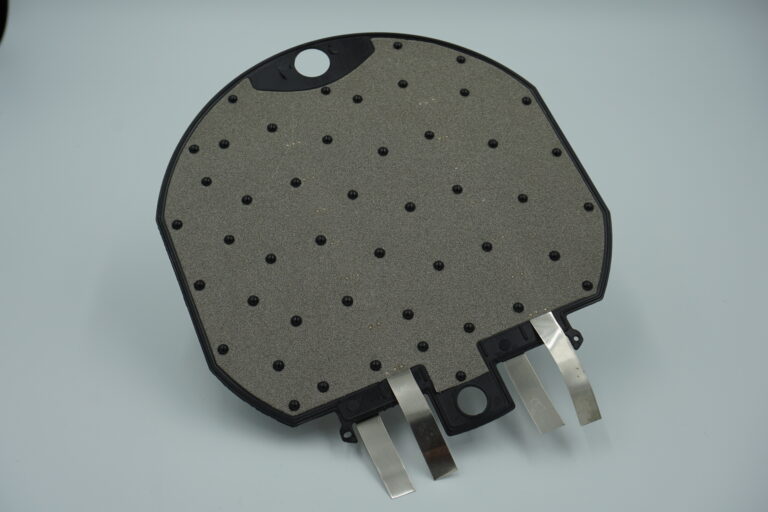

This video highlights TPI’s expertise in accurately heat staking a microfluidic diagnostic test card with seventeen extremely small posts. The system features a customized nest and clamping device to ensure precision on every run. Additionally, it incorporates a rotary table for easy loading and unloading, as well as increased production capacity.