Heat Swaging – A Specialized Form of Heat Staking in Thermoplastic Assembly

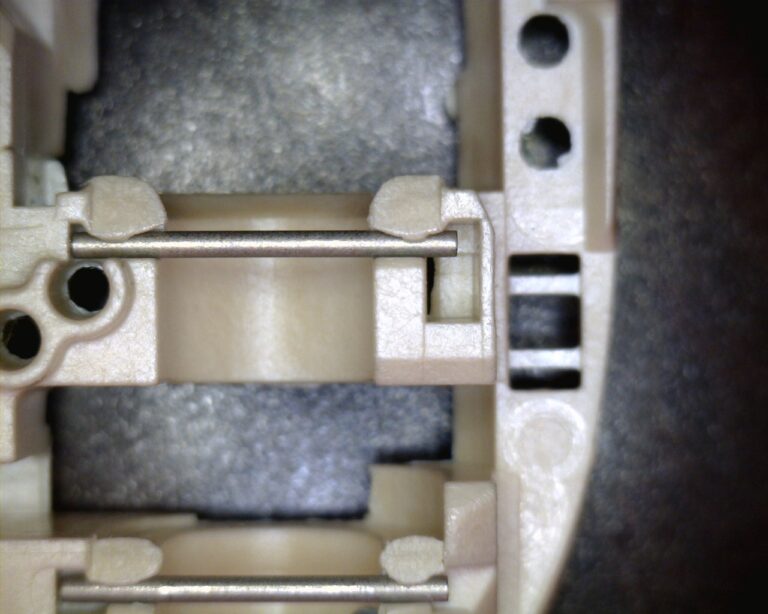

In the world of thermoplastic assembly, precision and strength are paramount. Among the various techniques used to join plastic components, heat staking and heat swaging

Heat swaging is a specialized form of heat staking and plays a vital role in thermoplastic assembly. Its ability to create strong, precise, and reliable bonds without additional materials make it an ideal choice for various industries, from automotive and electronics to medical devices and household appliances. By understanding the nuances of heat swaging, manufacturers can leverage this technique to enhance the durability and performance of their plastic assemblies.

In the world of thermoplastic assembly, precision and strength are paramount. Among the various techniques used to join plastic components, heat staking and heat swaging

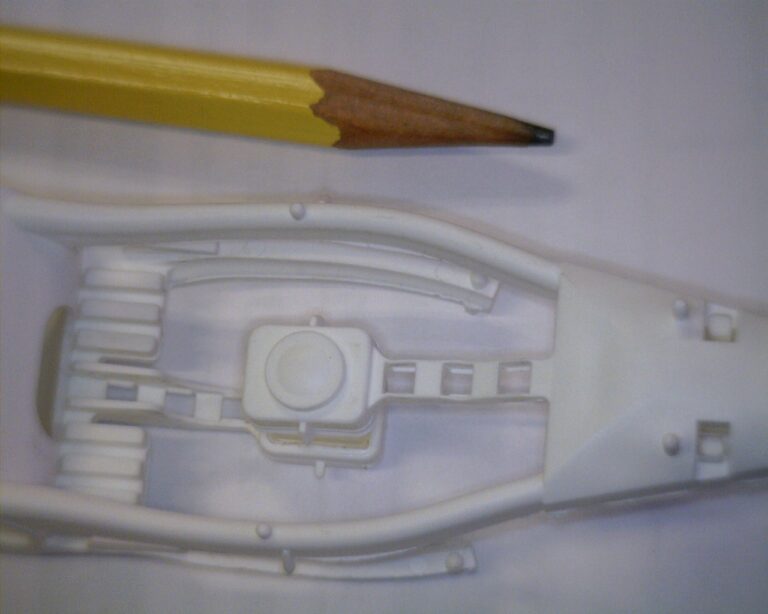

This video highlights our C-Series machine, equipped with a specialized striping feature that prevents device ejection after the heat swaging process. For increased productivity and ease of use, the machine incorporates a rotary table, streamlining both loading and unloading for efficient, high-output operation.

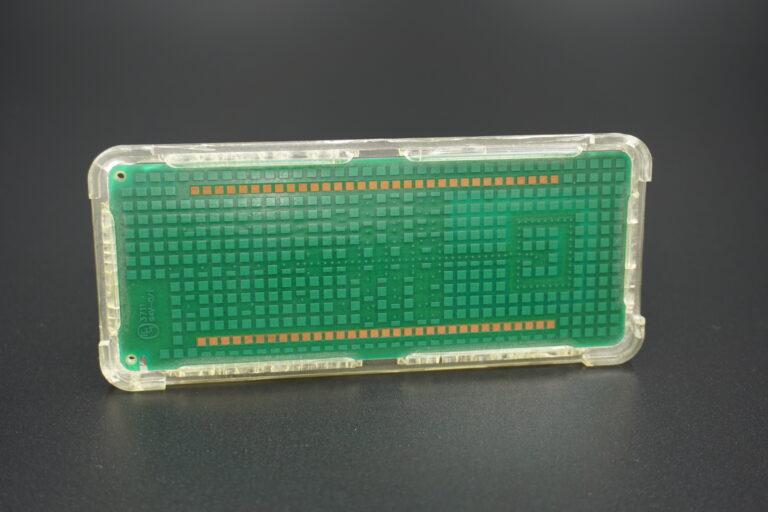

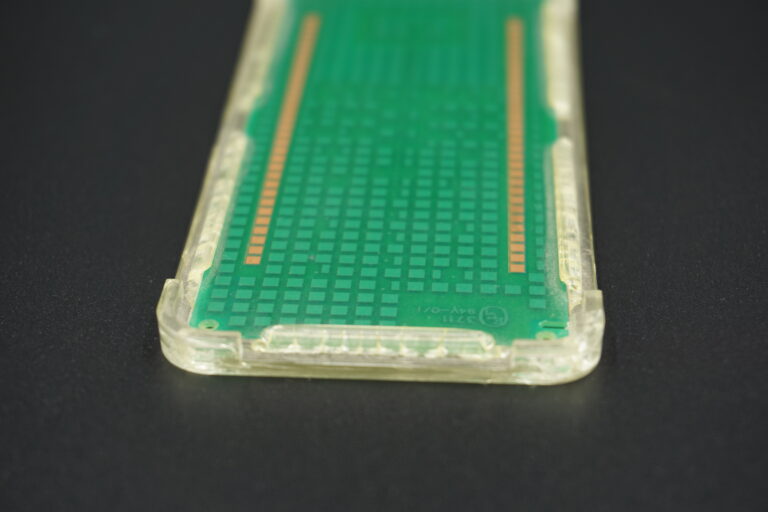

This video features a C-Series machine performing heat swaging, a form of heat staking, to secure piezoelectric sounders into a wearable medical device. The system is equipped with a rotary table for easy loading and unloading, providing increased production capacity. Additionally, the nesting fixture includes vacuum suction to securely hold the parts in place during the process.