Services

Thermal Plastic Assembly Process Development and Optimization Services

At Thermal Press International, we can support you through the entire product lifecycle by evaluating feasibility and developing optimal manufacturing plans for high quality and efficiency. We optimize assembly processes for strength, cycle time, and appearance, offering tailored design recommendations and prototype assembly. With the use of advanced 3D printing technology, we can quickly create prototypes that allow for rapid testing and design refinement. Whether you have detailed specifications or a rough outline, we help develop and refine your manufacturing concept, estimate equipment costs, and use CAD tools to verify design elements, ensuring your automation equipment meets all requirements. Let us transform your ideas into reality with our comprehensive expertise.

Prototyping

Design for Manufacturing (DFM)

During the product design stage, we collaborate to reduce manufacturing costs and identify/prevent discrepancies.

Concept Design

Translating ideas into viable product concepts.

Material Selection

Expert guidance in choosing materials aligned with your application requirements and budget constraints.

Cost Analysis

Leverage our decades of experience to ensure optimal material selection within budgetary constraints.

3D Printing

Rapid prototyping for iterative design refinement, saving time and costs before full-scale production.

R&D Services

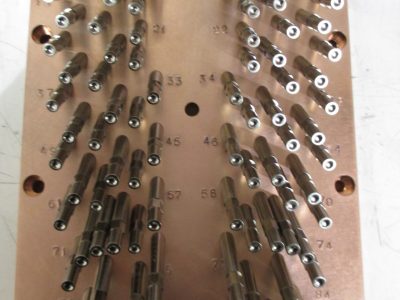

Fixturing Design

Custom fixtures to ensure accuracy, repeatability, and efficiency in your production process.

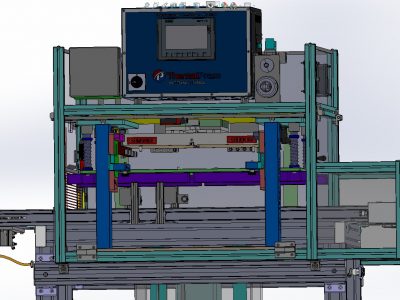

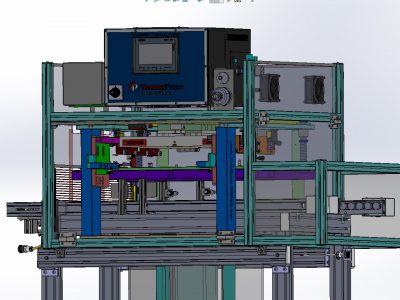

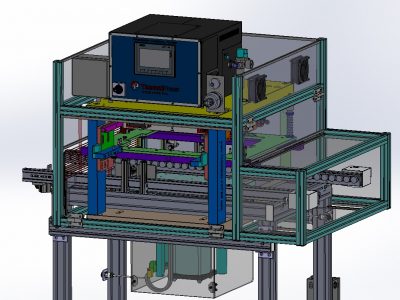

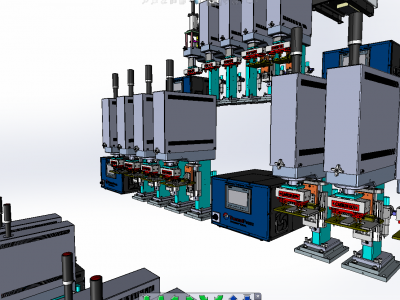

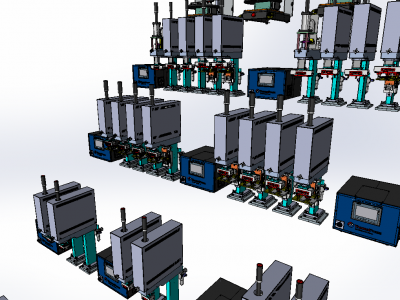

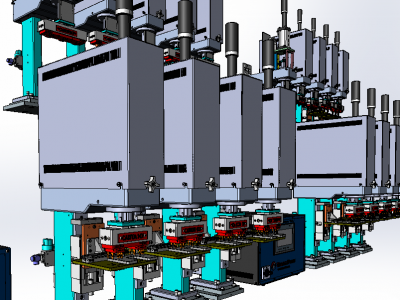

Automation Machine Design

Specialized machinery design to automate industrial processes, improving efficiency and consistency.

Process Development/Optimization

Enhanced manufacturing processes for increased efficiency, quality, and cost-effectiveness. Ergonomics always factored in prioritizing worker safety, comfort and efficiency.

Product Design and Optimization

Design Refinement

Refining and enhancing product designs for optimal performance and manufacturability.

Collaborative Approach

Collaborating on projects from rough concepts to detailed designs.

Optimization

Optimizing design elements for strength, material efficiency, and production cost.

Advanced Tools

Utilizing advanced CAD tools, 3D printing, and simulation technologies.

Meeting Requirements

Ensuring product design meets all functional, aesthetic, and technical requirements.

Quality Improvement

Reducing production challenges, minimizing waste, and improving product quality and reliability.

Pilot Runs

Small Batch Testing

Refining and enhancing product designs for optimal performance and manufacturability.

Real-world Validation

Real-world validation of equipment setup, assembly processes, and product performance.

Issue Identification and Risk Reduction

Early identification of potential product issues to ensure smooth full-scale production and reduction of manufacturing risks enhances confidence to scale up production.

Streamlined Production

Streamlined production with optimized cycle times and minimized costs.

Contract Assembly Services

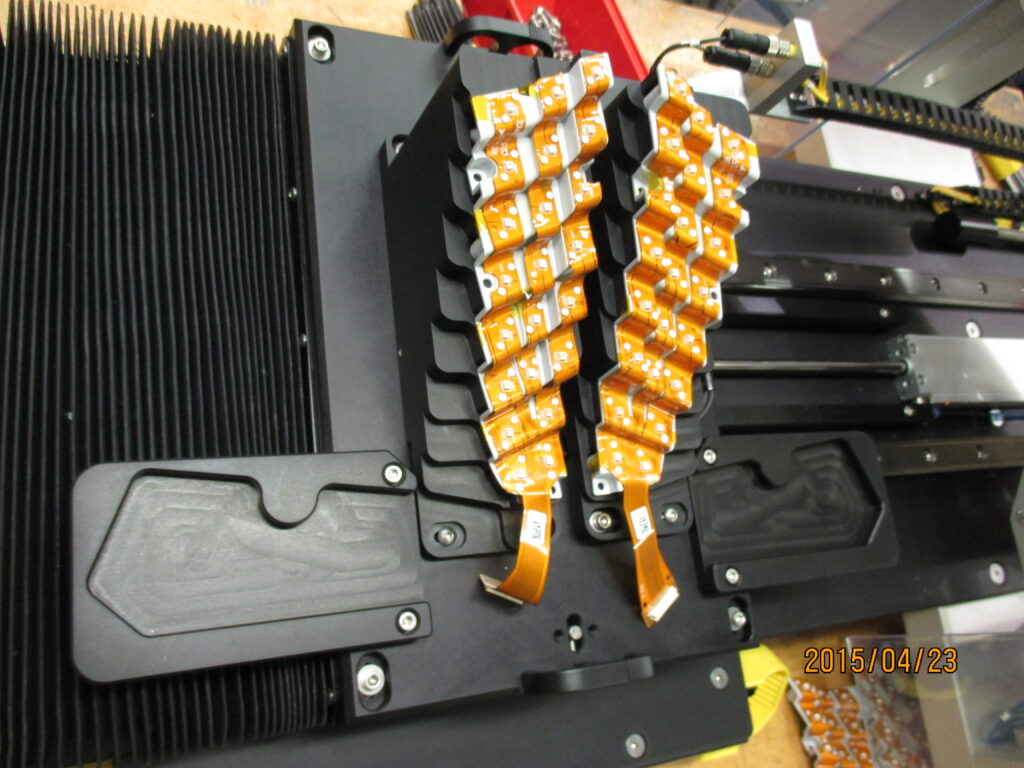

Electrical

Comprehensive electrical and electromechanical assembly services, including board-level assembly, chassis and rack panel wiring, front panel assembly, control panel/box assembly as well as electrical wire and cable harnesses.

Mechanical

Expert mechanical assembly capabilities for transforming components into fully assembled products from hardware installation to complete mechanical assembly involving dozens of subcomponents.

Plastics

Customized plastic assembly services including heat sealing, heat staking, and impulse sealing for permanent, effective assemblies.

At TPI, we understand the importance of meeting deadlines. Our dedicated project managers closely monitor each project, maintaining open communication channels with you throughout the process. Upload your design files, and we guarantee a response within one business day. Contact us today to streamline your manufacturing processes.

Industries Served

- Medical

- Automotive

- Aerospace

- Consumer Goods

- Electronics