Since its inception in 1976, Thermal Press International (TPI) has consistently set the benchmark in the industry for cutting-edge heat staking equipment and solutions. Offering a comprehensive range of innovative products and accessories, TPI remains the go-to choice for businesses seeking precision, reliability, and versatility in their thermal assembly processes.

Versatility Redefined: C-Series and H-Series Thermal Press Systems

At the core of TPI’s offerings are the highly adaptable C-Series and H-Series Thermal Press systems. Whether you’re tackling routine applications or demanding tasks requiring higher mating forces, these systems deliver exceptional performance. The C-Series boasts full self-containment and flexible retooling capabilities, making it an ideal fit for diverse heat staking needs. Meanwhile, the H-Series is engineered for rigorous applications, seamlessly integrating into conveyor-based systems and automation lines while maintaining precise thermal staking points.

Scaling Efficiency: Multi-Workstation and Servo Spin Actuators

For businesses aiming to scale up their thermal assemblies, TPI offers Multi-Workstation Thermal Press systems engineered for scalability and seamless integration. These workstations facilitate quick-change tooling and incorporate advanced digital controls for consistent assemblies. Moreover, TPI’s servo spin actuators elevate heat-staking machinery with unparalleled precision, offering programmable motion controls and multiple motion profiles for precise actuation requirements.

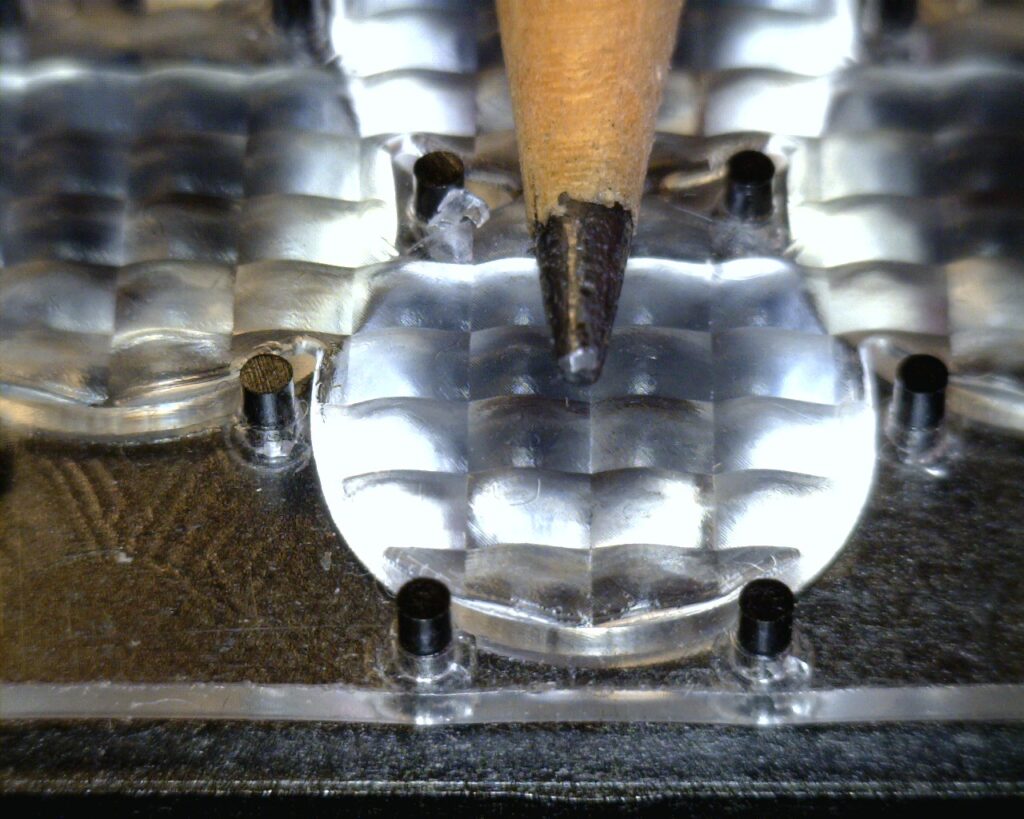

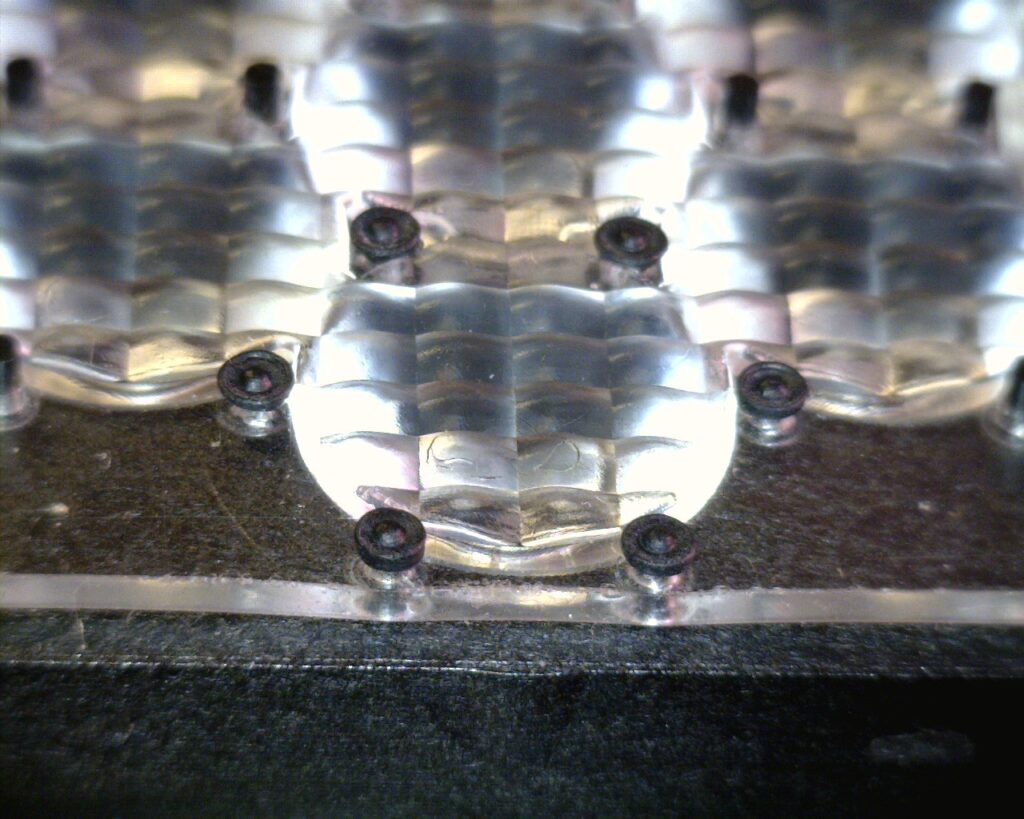

Compact Precision: MicroLAB Thermal Press

In industries where precision is paramount, such as medical device assembly, TPI’s MicroLAB Series Thermal Press excels. Despite its compact footprint, the MicroLAB offers all the features of larger production systems. Customizable with a range of tooling and actuation packages, this system is tailor-made for miniature to small-sized assembly applications, making it an indispensable asset for clean rooms and laboratory environments.

Streamlined Production: Power Shuttle Tables

TPI understands that every manufacturing process is unique. That’s why we offer power shuttle tables designed to streamline semi-automatic production. With varied configurations and actuating mechanisms, these tables accurately index items in and out of machinery, facilitating efficient heat staking processes. With options for servo and pneumatic actuation, TPI’s power shuttle tables provide the flexibility needed for diverse production environments.

Unlock Your Heat Staking Potential with Thermal Press International

When it comes to complex heat staking requirements, TPI has the expertise and tooling needed to deliver superior results. Whether you’re pulse heating, deforming, or reforming materials, our solutions ensure precision and reliability every step of the way. Experience the difference with TPI and elevate your heat staking processes today!

Contact Us: Contact Thermal Press International at (925) 454-9800 to speak with an engineer and explore how heat staking can optimize your manufacturing operations.