Traditionally, attaching metal grilles and screens to plastic frames has involved the use of additional fasteners, including screws, clips, rivets, or adhesives. However, these methods come with inherent costs, inventory management challenges, and varying levels of quality consistency.

The emergence of heat staking and swaging processes has revolutionized product design and assembly practices for many manufacturers. These techniques offer a cost-effective solution, often requiring minimal adjustments to existing injection molding tools. Moreover, products assembled through heat staking or swaging often exhibit superior strength and durability compared to those relying on traditional hardware attachments.

- The benefits of transitioning to heat staking or swaging are numerous:

- Elimination of rattles caused by loose fasteners.

- Prevention of screens or grilles becoming loose over time.

- Enhanced tamper resistance of products.

- Increased production rates with a smaller workforce.

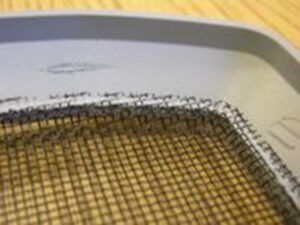

In the provided images above, heavy-duty construction-grade screens are seamlessly integrated into plastic vent housing using heat staking. Similarly, in the images below black-painted grilles are swaged into the rib of plastic engine frames, offering a secure and aesthetically pleasing attachment.

The swaging process involves embedding the metal grille directly into the plastic, requiring precise control of heat and pressure. Thermal Press International (TPI) employs advanced machine controls and quality tooling to ensure consistent and reliable assemblies.

Moreover, heat staking and swaging are versatile techniques that can accommodate various screen materials, including nylon, felt, and fabric. If you’re considering adopting heat staking or swaging for your application, our team of engineers at TPI is ready to assist.