Heat staking is a thermal assembly process used to join thermoplastic components to other materials (including dissimilar plastics or metals) by melting or deforming a plastic post with controlled heat and pressure. This technique is ideal for:

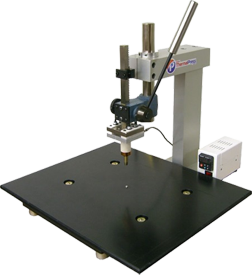

Our thermal press systems offer tight process control, interchangeable tooling, and scalability – making them ideal for heat staking operations in both R&D and high-volume production. No other machine on the market today offers such precision.

All of the following TPI machines can be configured for heat staking:

These systems support advanced process features like:

Custom Tooling & Integration

Thermal Press International’s heat staking equipment is trusted across a wide range of industries and precision plastic assembly needs. Explore some of the most common heat staking applications we support:

Talk to Our Engineers