Understanding the Heat Staking Process: A Comprehensive Guide

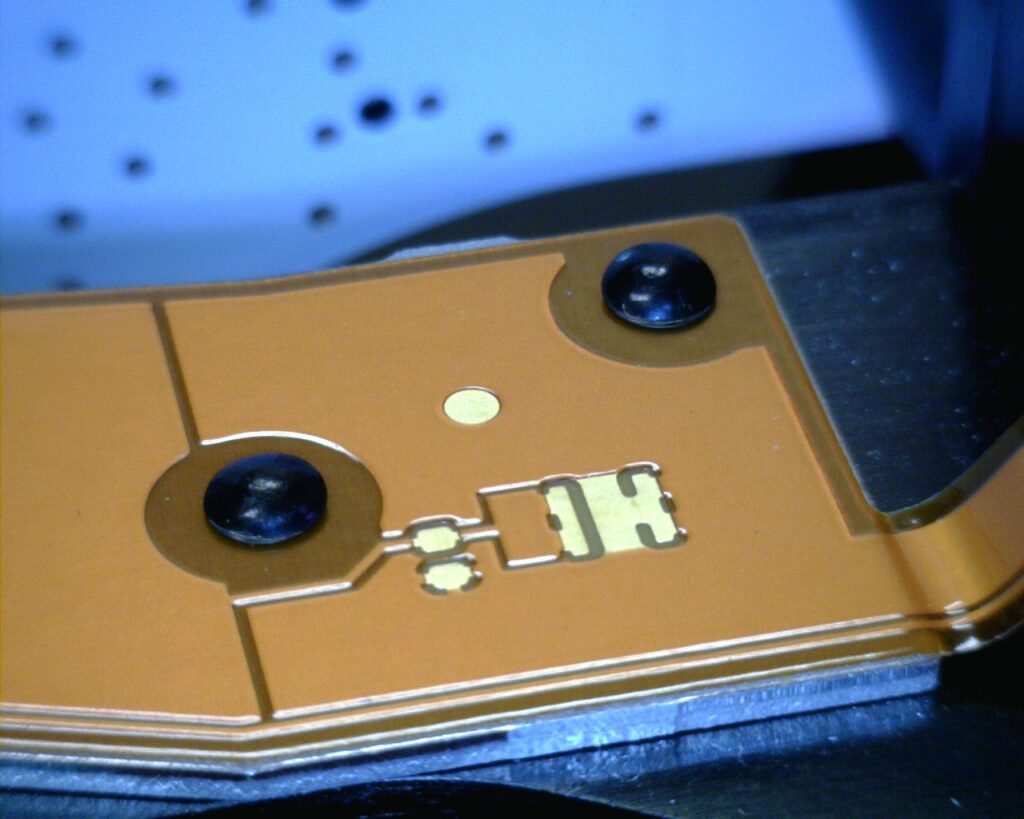

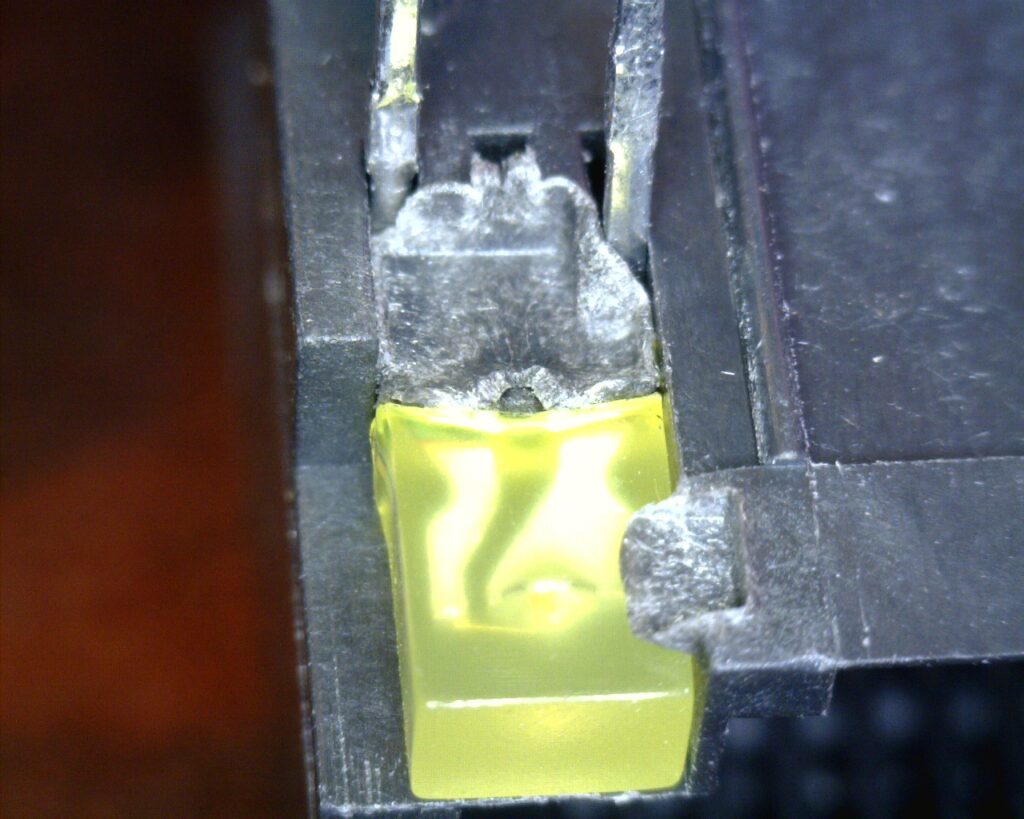

Heat staking stands as a fundamental process in modern manufacturing, offering a reliable means to mechanically lock thermoplastic components in place through controlled heating and

Heat staking is a versatile and efficient assembly technique in the manufacturing of products with built-in LED lighting. It provides secure assembly, enhances structural integrity, allows for design flexibility, reduces costs, improves heat management, and offers environmental benefits. These advantages make heat staking a preferred method in various industries including consumer electronics, automotive, home appliances, and medical devices.

Heat staking stands as a fundamental process in modern manufacturing, offering a reliable means to mechanically lock thermoplastic components in place through controlled heating and

In the dynamic realm of automotive innovation, one aspect stands out: the evolution of LED technology. As a frontrunner in precision heat staking machinery, Thermal

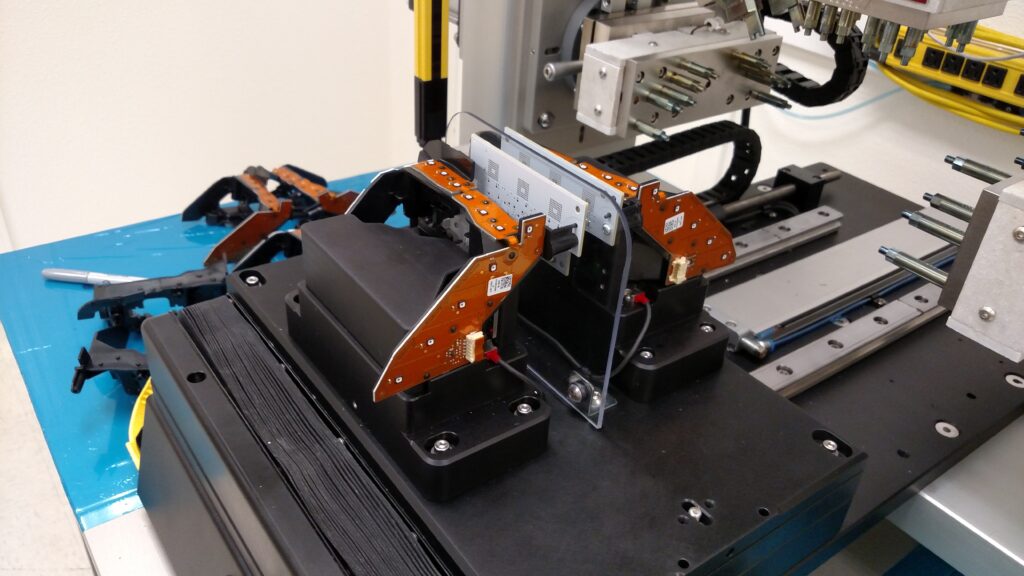

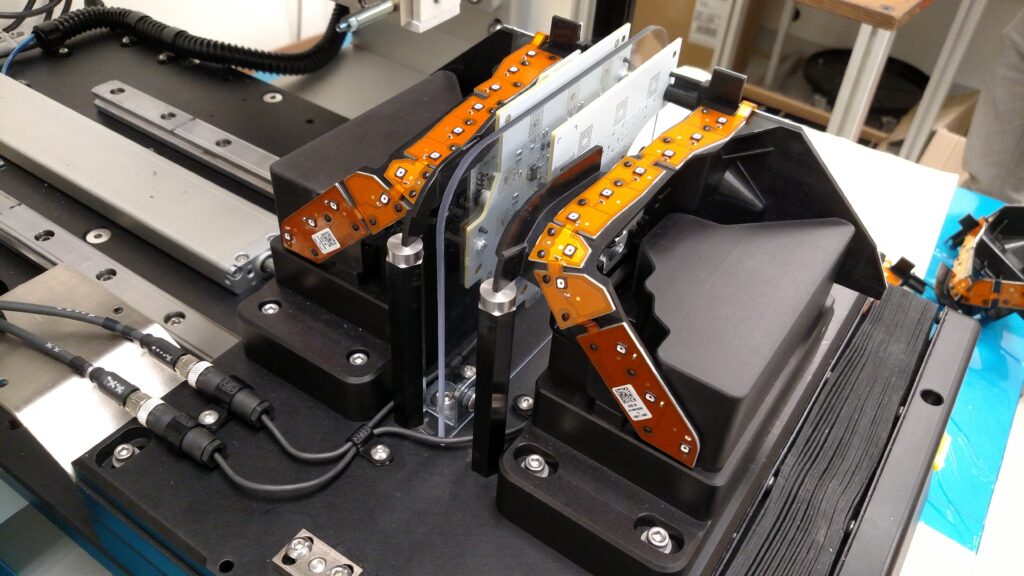

This video showcases a specially customized H-Series machine, equipped with four distinct thermal heads for optimized versatility. It also features a power shuttle table for enhanced efficiency. To ensure operator safety, the machine is designed with dual-hand Opto button controls, requiring both hands to be engaged before initiating each cycle.

This video showcases a custom-format Thermal Press machine engineered to heat stake a large automobile taillight assembly. The system features a multi-actuator setup and multiple thermal heads, ensuring precise and efficient processing of this complex component.

This video features an H-Series Thermal Press utilizing a power shuttle table to streamline the loading and unloading of an LED lighting fixture. It is equipped with a custom clamping system to ensure accurate positioning on every run.