Medical Device Trends for 2025 and Beyond: Innovation in Action

The global medical device industry continues to evolve at a remarkable pace. As we move deeper into 2025, key trends are shaping the future of healthcare by delivering smarter, safer, and more connected solutions. The market is projected to reach a global value of $850 billion by 2030, with an annual growth rate of 5.2%. […]

Reshoring Medical Device Manufacturing: How Thermal Press International Can Help

As medical device manufacturers consider reshoring production to the USA to avoid import tariffs, they face challenges such as improving supply chain resilience and ensuring a cost-effective and timely transition. With nearly 50 years of industry expertise, Thermal Press International (TPI) provides turnkey thermal press solutions that streamline medical device assembly and domestic manufacturing. Why […]

MD&M West 2025: A Successful Event for Thermal Press International

The MD&M West tradeshow in Anaheim, CA was another outstanding event for Thermal Press International (TPI)! Our booth was bustling with activity throughout the show, as we had the opportunity to connect with both existing and new customers across the medical device manufacturing industry. Among our existing customers, many stopped by to pay their respects […]

Streamlining Medical Device Assembly

In an ever-evolving medical landscape, flawless assembly of every unit, every time, is imperative. Our automated medical device assembly equipment empowers your organization to meet demand while ensuring a seamless, high-quality manufacturing process. Automating Medical Device Assembly As the demand for medical devices continues to surge, Thermal Press International (TPI) offers innovative manufacturing and automation […]

Enhancing the Manufacturability of Medical Test Devices: Filters and Films in Thermal Plastic Assembly

In the realm of medical diagnostics, precision, reliability, and efficiency are paramount. From rapid tests for infectious diseases to advanced diagnostic tools, the accuracy of medical test devices often hinges on the quality of their components and assembly. Among the critical elements in the manufacturing process are filters and films, which play a pivotal role […]

Medical Device Trends for 2024 and Beyond

With the rapid development of new prototypes and changing consumer perceptions of healthcare, the medical device market is experiencing significant growth. According to recent market research, the industry is projected to grow annually by 5.2% from 2023 to 2030, reaching a global market value of $850 billion. Below, we explore some of the medical device […]

New Developments in Internet of Things (IoT) – Connected Medical Devices and Plastic Assembly – 2023

The fourth industrial revolution holds considerable promise for the internet of medical things (IoMT) and the plastic assembly industry. Currently, the IoMT focuses on infection tracking, automation of manual processes, and leveraging healthcare data to meet improved patient outcomes. In 2023, medical device manufacturers will begin leveraging analytics, artificial intelligence, cloud, automation, and big data to drive […]

Precision Heat Sealing Solutions for Compact Medical Devices

At Thermal Press International (TPI), we understand the critical importance of creating reliable, consistent, and high-quality seals for compact medical devices. With our state-of-the-art heat press equipment, we offer advanced solutions tailored to meet the unique challenges of heat sealing and staking in the medical industry. Precision Engineering for Compact Medical Devices Heat sealing and […]

Revolutionizing Bioreactor Bag Sealing and Manufacturing with Thermal Press International

Since our inception in 1976, Thermal Press International (TPI) has been at the forefront of precision thermal and plastic assembly technologies, pioneering the development of thermal press machines. Today, we remain an industry leader in producing equipment for manufacturing high-quality bioreactor bags across various sectors. Why the Shift to Bioreactor Bags? Research conducted by BioPlan […]

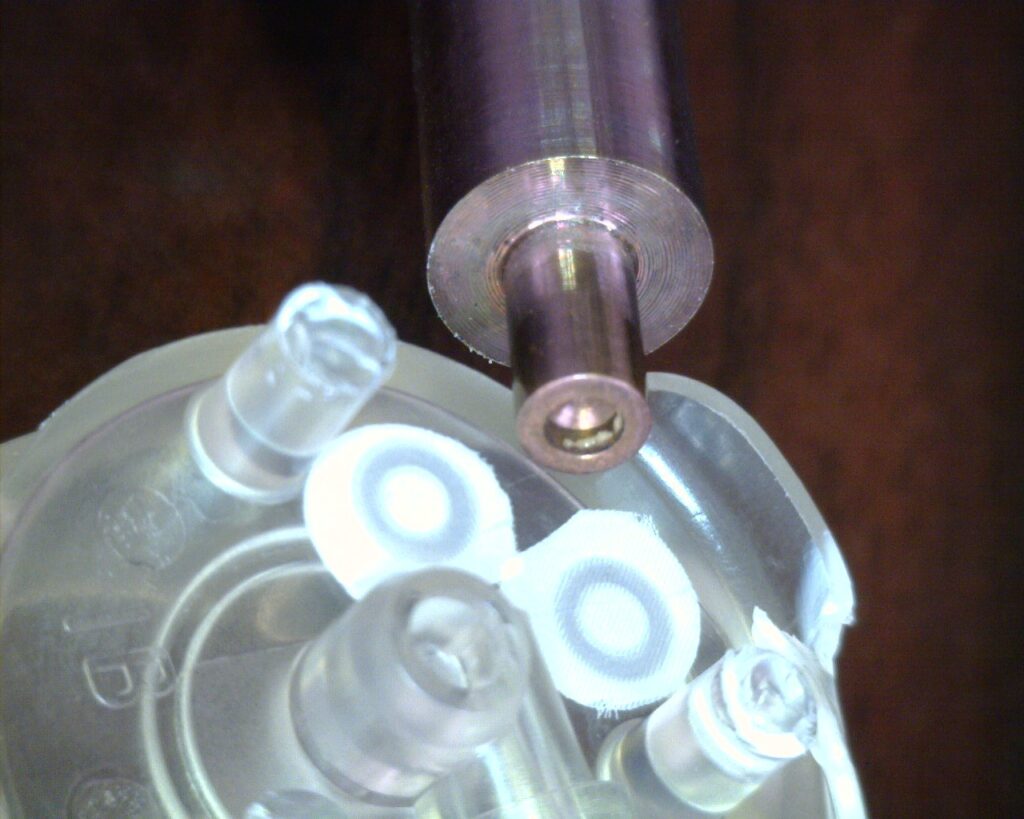

Port Sealing: An Effective Heat Sealing Solution

Low-Cost Convenience For Prototyping Heat sealing is the process of sealing one thermoplastic to another similar thermoplastic using heat and pressure. The direct contact method of heat sealing utilizes a constantly heated die or sealing bar to apply heat to a specific contact area or path to seal or weld the thermoplastics together. Heat sealing […]