At Thermal Press International (TPI), we understand the critical importance of creating reliable, consistent, and high-quality seals for compact medical devices. With our state-of-the-art heat press equipment, we offer advanced solutions tailored to meet the unique challenges of heat sealing and staking in the medical industry.

Precision Engineering for Compact Medical Devices

Heat sealing and staking are intricate processes that demand unparalleled precision, especially when working with compact medical devices such as microfluidic devices, implantable sensors, intravascular devices, drug delivery systems, and miniature implantables. With a TPI machine, you gain precise control over pressure, temperature, and substrate positioning, ensuring optimal sealing performance for even the most intricate assemblies.

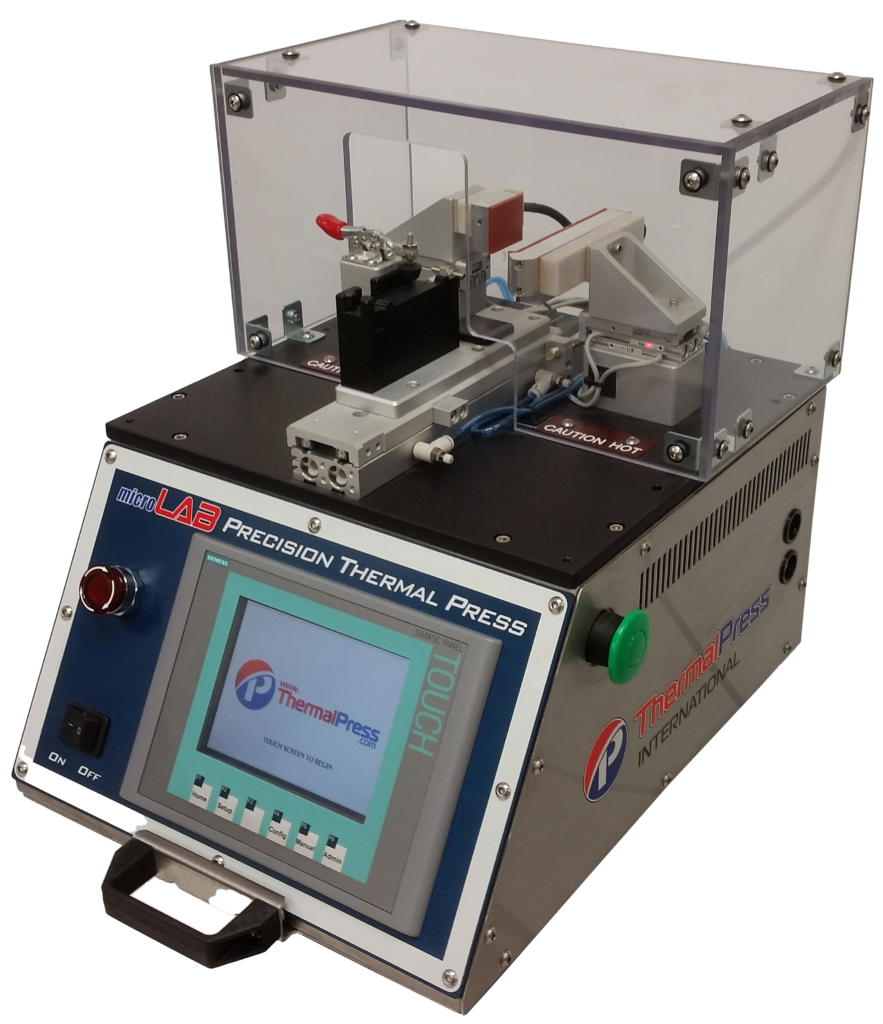

Introducing the MicroLAB Thermal Press System

Our MicroLAB Thermal Press system is a game-changer, offering a completely self-contained solution designed specifically for clean rooms and laboratories. With its compact footprint and industrial-grade performance, the MicroLAB system allows you to configure your heat press for miniature to small-sized assemblies with ease.

Versatile Configuration Options

Whether you’re working on an established product line or launching a new device, TPI has the expertise and flexibility to support your project. We collaborate closely with your team to develop a repeatable and versatile heat sealing assembly process. Ther MicroLAB system can be adapted with:

- Roll feed systems, including rotary table configurations

- Pneumatic clamping solutions and power shuttle tables for semi-automated production processes

- Advanced motion and process control using servo actuators and safety light curtain systems

Advanced Motion Control for Precision

Compared to standard pneumatic actuators, our servo actuators provide advanced motion and distance control, allowing you to program multiple motion profiles and recipes with ease using the integrated touchscreen interface. Your setups are protected with operator password functionality, ensuring security and consistency in your assembly process.

Streamlined Assembly Process with Quick Change Tooling

Adapting the MicroLAB system to your assembly process is seamless with quick change tooling setups. We offer a range of actuation packages, including vertical, horizontal, stepper, indexing, and spin or rotational options, allowing you to configure the MicroLAB system to suit your specific design requirements and ensure a quality sealing procedure every time.

Comprehensive Support and Training

TPI provides extensive engineering and technical support, ensuring you can optimize your processes or develop new ones with confidence. Our team is committed to helping you establish a consistent and repeatable assembly process, reducing error rates, and enhancing product verification and validation tasks. We also offer training and preventative maintenance services to ensure ongoing support foy your team.

Innovate Your Product Assembly Line with Thermal Press International

If you’re seeking a versatile platform that delivers precision and control for compact medical device assembly, TPI can help. Our solutions are backed by medical validation and qualifications, and our team is dedicated to guiding you through setup, calibration, and beyond. With TPI by your side, you can accelerate your manufacturing process, enhance product quality, and achieve peace of mind knowing your seals are secure and reliable.

Contact Us: Contact Thermal Press International at (925) 454-9800 to speak with an engineer and explore how heat staking can optimize your manufacturing operations.