When it comes to manufacturing plastics, the quality of your end product hinges on the precision and reliability of your assembly tooling. At Thermal Press International (TPI), we understand the crucial role that tooling plays in ensuring the success of heat staking, heat sealing, and other assembly processes. With nearly five decades of expertise, we specialize in designing and manufacturing interchangeable tooling solutions for a wide range of industries, including medical, automotive, consumer products, electronics, and aerospace.

Benefits of Thermal Press International Plastic Assembly Tooling

- Medical Equipment Manufacturing: Our plastic assembly equipment and interchangeable tooling packages are ideal for manufacturing various medical equipment, including bioreactor and medical fluid bags, invitro diagnostics, and implantables. With specialized port and fitment sealing options, our heat sealing machines offer unparalleled efficiency and reliability, meeting the stringent standards of the medical industry.

- Automotive Lighting and Infotainment Systems: Heat staking plays a critical role in automotive lighting and infotainment systems, impacting the quality of trim packages and aesthetics. Our scalable solutions, such as the C-Series or H-Series Thermal Press systems with custom heat stake tooling packages, ensure exceptional results through advanced materials, vision controls, and reliable thermal characteristics.

- Wearable Medical Devices: TPI’s heat sealing machines are indispensable for manufacturing wearable medical components like drug delivery systems, monitors, and insulin pumps. Our customized tooling solutions facilitate adhesive patch welding and septum swaging onto reservoirs, meeting the rigorous standards required for medical devices.

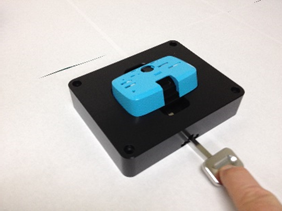

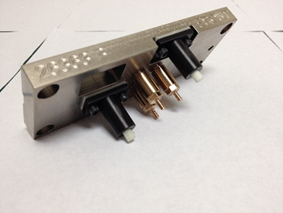

- Customized Tooling Solutions: We collaborate closely with our clients to design customized plastic assembly tooling that precisely meets their specifications. From shape and texture to material type and spacing, we ensure that every aspect of the tooling aligns with our clients’ unique requirements.

Why Choose Thermal Press International?

- Rigorous Testing: Our heat sealing and staking tooling products undergo rigorous testing to ensure worry-free operation, superior throughputs, and machine longevity.

- Efficiency and Productivity: Heat staking allows for all operations to be executed in a single motion, leading to faster and more efficient manufacturing processes. Clients appreciate higher productivity through faster setup, quicker tooling change-overs, and reduced downtime compared to other assembly methods.

- Precision manufacturing: We manufacture all tooling to tight specifications, ensuring consistency and reliability. Most standard parts, tooling, and accessories are readily available for purchase, providing convenience and accessibility to our clients.

Partner with TPI for precision tooling solutions that elevate your plastic assembly processes and deliver exceptional results across diverse industries. Experience the difference of reliable tooling backed by decades of expertise and unparalleled customer support.

Contact Us: Contact Thermal Press International at (925) 454-9800 to speak with an engineer. Let us help you elevate your plastic assembly processes and drive innovation in your industry.