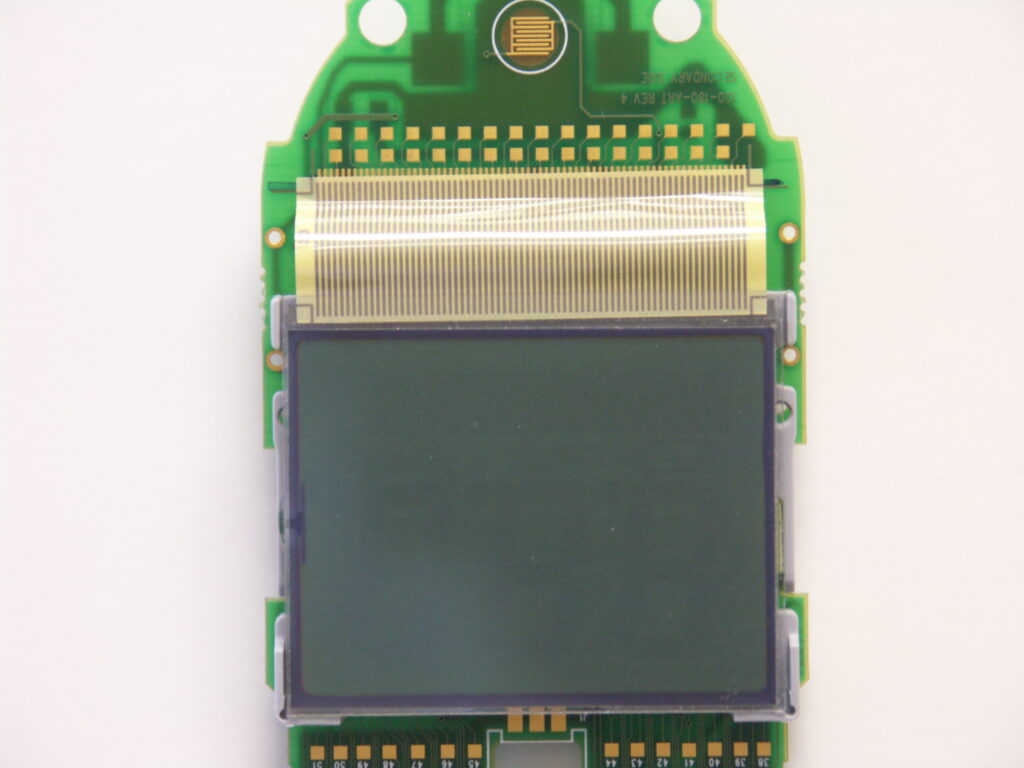

In the realm of plastic assembly, particularly in the domains of anisotropic and formono-isotropic liquid crystal display (LCD) assembly, heat seal connectors (HSCs) to printed circuit boards (PCBs), and front panel displays, Thermal Press International (TPI) leads the way with its precision equipment designed to apply exacting temperature and pressure. Our method for bonding connectors to LCDs, PCBs, and various substrates ensures consistently high-quality sealed bonds through meticulous control of process parameters.

HSCs, comprised of electrically conductive traces on thin polyester films, are bonded to substrates using thermosetting anisotropic or mono-isotropic adhesives, containing dispersed electrically conductive particles.

Bonding Parameters:

Effective bonding necessitates a delicate balance of temperature and pressure. Typically, temperatures exceeding 120°C (248°F) and pressures of at least 20 kg/cm2 (PSI) are applied for a minimum of 5 seconds to achieve optimal bonding. While these parameters serve as a baseline, each application demands a tailored approach based on substrate types, connector specifications, and process requirements.

Assembly Procedures:

The process of bonding connectors to substrates involves meticulous steps to ensure precision and reliability. Cleaning the substrate and HSC is imperative, followed by precise positioning of the HSC using visual or mechanical alignment methods. Post-bonding, thorough inspection ensures trace alignment, electrical continuity, and bond strength.

Common Assembly Issues:

While the HSC assembly process boasts minimal variability, rejected assemblies may occur due to factors like inadequate bond strength, misalignment, or component damage. To mitigate these issues, adherence to application requirements is crucial, including timely use of HSCs, maintaining blade planarity, and employing interposer materials for consistent thermal and pressure dispersion.

Plastic Connector Bonding Machines:

Equipment selection plays a pivotal role in achieving consistent and repeatable results. Manual arbor presses, though feasible, often fall short due to inconsistencies in pressure and dwell time. High-quality equipment designed specifically for HSC assembly is preferred, ensuring precise application of pressure and temperature while maintaining blade planarity.

Conclusion:

TPI offers state-of-the-art equipment and expertise to address even the most demanding sealing and connector bonding requirements. Our solutions are tailored to optimize efficiency, reliability, and cost-effectiveness throughout the engineering, design, prototype development, and manufacturing phases. Partner with us to unlock the full potential of your plastic assembly processes and achieve significant cost savings without compromising on quality.

Contact Us: Contact Thermal Press International at (925) 454-9800 to speak with an engineer and explore how heat staking can optimize your manufacturing operations.