Plastics are widely used in modern product designs due to their versatility, low cost, and superior performance characteristics. Compounds like acetals, polypropylenes, and polyethylenes offer flexibility and durability, making them popular with designers. However, joining these parts together in plastic assemblies requires special consideration, as plastics can be challenging to glue.

How to Bond Plastics That Are Hard to Glue?

Modern plastics are difficult to glue because they often lack sufficient surface tension. To effectively bond plastics, a primer or promoter is often required to alter the molecular properties of the surface, establishing the necessary clamp load.

While primers and promoters can improve adhesion under ideal conditions, glued joints are still prone to degradation from air or water penetration. Even with these preparations, using glue for plastic assembly faces several challenges:

- Curing Time: Adhesives require a longer time to cure to achieve the required bond strength.

- Environmental Sensitivity: Bonding depends on physical and chemical conditions that may change with aging.

- Safety Concerns: Glues are often hazardous and require special protective controls to avoid human exposure.

- Surface Preparation: Gluing plastics requires thorough cleaning and preparing the surface before adhesion.

Although bonds using promoters and glues can overcome some challenges in clamp load, the increased cycle time required for each assembly makes them less ideal for manufacturing applications. Industries like automotive parts, medical devices, and modern electronics need better solutions to maintain throughput without increasing product liability.

Why Heat Staking or Heat Sealing with a Thermal Press is the Better Choice?

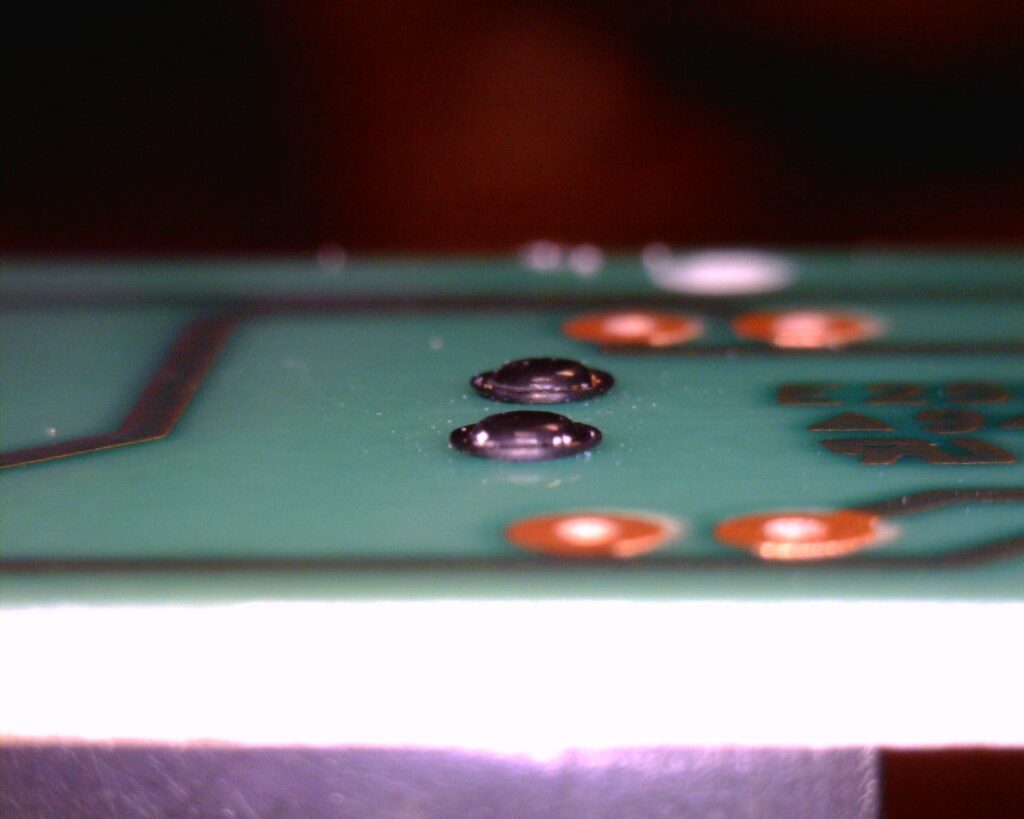

- Thermal press bonding techniques consistently outperform glues in manufacturing applications. These platforms are versatile enough to support a variety of bonding approaches, including heat staking, hot bar soldering, swaging, insertion and film/filter welding or heat sealing.

Advantages of Thermal Press Solutions:

- Precision: Program precise recipes for every assembly, ensuring consistent and repeatable results.

- Efficiency: Advanced bonding techniques that require heat activation of the adhesive save precious curing time.

- Versatility: Supports multiple bonding methods, allowing for flexibility in manufacturing processes.

Improve the Quality of Clamp Loads for Your Plastic Assemblies with Thermal Press International

Thermal Press International is a leading provider of heat sealing and heat staking equipment. Our solutions ensure streamlined operations and improved product quality with consistent and repeatable joints between two or more plastic parts. With a variety of platforms available and the ability to quickly change tooling, you can ensure each bond has the required clamp load without needing to glue your plastic parts together.

Contact Us or call (925) 454-9800 to speak with a Thermal Press engineer.