In the realm of medical diagnostics, precision, reliability, and efficiency are paramount. From rapid tests for infectious diseases to advanced diagnostic tools, the accuracy of medical test devices often hinges on the quality of their components and assembly. Among the critical elements in the manufacturing process are filters and films, which play a pivotal role in ensuring the efficacy and integrity of these devices. In this article, we explore enhancements in medical test device manufacturability that utilize filters and films in the context of Thermal Press International’s cutting-edge thermal plastic assembly equipment.

The Crucial Role of Filters and Films

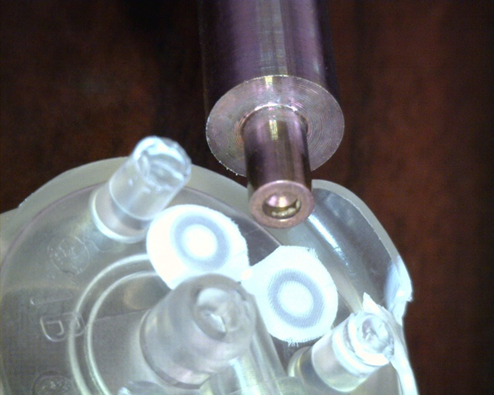

Filters and films serve a multitude of functions within medical test devices, ranging from facilitating fluid flow to providing structural support and maintaining sterility. In diagnostic assays, filters are instrumental in separating components, removing impurities, and ensuring precise sample delivery. Meanwhile, films act as barriers, protecting sensitive components from contamination and environmental factors while also providing a substrate for various assay components.

Precision Manufacturing with Thermal Plastic Assembly Equipment

Machines designed specifically for thermal plastic assembly, such as those offered by Thermal Press International (TPI), upgrade and simplify the manufacturing process of medical test devices. These advanced machines leverage heat and pressure with great precision and accuracy to seamlessly bond components, ensuring tight seals and perfect alignment. From microfluidic cartridges to lateral flow assays, thermal plastic assembly equipment offers unmatched versatility and efficiency in producing complex medical devices.

Optimizing Performance with Quality Materials

The efficacy of medical test devices hinges not only on the assembly process but also on the quality of materials used. Filters and films must meet stringent criteria for compatibility, chemical resistance, and optical clarity. With TPI’s expertise in thermal plastic assembly, manufacturers can integrate these materials seamlessly, optimizing device performance and reliability.

Tailored Solutions for Diverse Applications

One of the hallmark features of TPI’s equipment is its adaptability to diverse applications and materials. Whether manufacturing point-of-care diagnostic test devices or laboratory-grade assays, the flexibility of thermal plastic assembly equipment enables manufacturers to tailor solutions to specific requirements. This versatility ensures that medical test devices meet the highest standards of quality and performance across a spectrum of healthcare settings.

Innovation Driving Progress

As the field of medical diagnostics continues to evolve, innovation in materials and assembly techniques remains paramount. Thermal Press International is at the forefront of this innovation, continually refining its equipment to meet the evolving needs of the healthcare industry. By collaborating with manufacturers and leveraging cutting-edge technology, TPI facilitates the development of next-generation medical test devices that are accurate, reliable, and accessible.

Conclusion

In the intricate landscape of medical diagnostics, every component plays a crucial role in ensuring the accuracy and reliability of test results. Filters and films, alongside advanced thermal plastic assembly equipment from TPI, form the backbone of manufacturing processes for medical test devices. By prioritizing precision, quality, and innovation, manufacturers can continue to push the boundaries of diagnostic capabilities, ultimately improving patient care and outcomes worldwide.

Contact Us: Contact Thermal Press International at (925) 454-9800 to speak with an engineer and explore how heat staking can optimize your manufacturing operations.