The Thermal Press Difference

Thermal Press International, Inc. (TPI) has been a pioneer in thermal press machines, technologies, and customized solutions for nearly 50 years. Specializing in heat staking, heat sealing, thermal insertion and swaging equipment, we serve industries including medical, electronics, automotive, computer, and many others. Our customers rely on our expertise and continually return for new products. […]

Maximizing Productivity with Heat Sealing Solutions from Thermal Press International

Thermal Press International (TPI) is at the forefront of providing top-quality heat sealing solutions for various industries. Our range of heat sealing machines is designed to meet the diverse needs of businesses, ensuring precise and reliable seals for a wide array of materials including foil, plastic, and film. Whether you’re in the medical, automotive, electronics […]

Medical Device Trends for 2024 and Beyond

With the rapid development of new prototypes and changing consumer perceptions of healthcare, the medical device market is experiencing significant growth. According to recent market research, the industry is projected to grow annually by 5.2% from 2023 to 2030, reaching a global market value of $850 billion. Below, we explore some of the medical device […]

New Developments in Internet of Things (IoT) – Connected Medical Devices and Plastic Assembly – 2023

The fourth industrial revolution holds considerable promise for the internet of medical things (IoMT) and the plastic assembly industry. Currently, the IoMT focuses on infection tracking, automation of manual processes, and leveraging healthcare data to meet improved patient outcomes. In 2023, medical device manufacturers will begin leveraging analytics, artificial intelligence, cloud, automation, and big data to drive […]

Optimizing Uptime in Your Plastic Assembly Process

To manufacture high quality plastic products within a reasonable time frame and budget, an efficient assembly process is key. However, several factors can prolong assembly time, costing your company both time and money. To enhance your assembly process and boost production, it is crucial to calculate uptime accurately and identify potential time losses. Four Common […]

Plastic Welding’s Role with Thermal Assembly

Plastic welding enables the creation of a molecular bond between thermoplastic materials, ensuring exceptional strength and durability. This process minimizes the need for frequent repairs or replacements, making it a cost-effective solution for manufacturers. At Thermal Press International (TPI), we offer comprehensive consultation services to help determine the optimal assembly process for your applications and […]

Precision Heat Sealing Solutions for Compact Medical Devices

At Thermal Press International (TPI), we understand the critical importance of creating reliable, consistent, and high-quality seals for compact medical devices. With our state-of-the-art heat press equipment, we offer advanced solutions tailored to meet the unique challenges of heat sealing and staking in the medical industry. Precision Engineering for Compact Medical Devices Heat sealing and […]

5 Easy Design-for-Manufacturability Ideas

When developing new products, considering the entire production lifecycle early on is critical to ensuring a smooth transition to manufacturing. By incorporating manufacturing and assembly considerations into the design phase, you can save both time and money during production. Since the final product price plays a key role in its market viability, optimizing your design […]

Mastering Heat Sealing: Optimizing Procedures and Parameters for Plastic Assembly

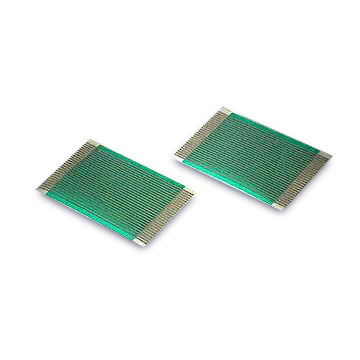

In the realm of plastic assembly, particularly in the domains of anisotropic and formono-isotropic liquid crystal display (LCD) assembly, heat seal connectors (HSCs) to printed circuit boards (PCBs), and front panel displays, Thermal Press International (TPI) leads the way with its precision equipment designed to apply exacting temperature and pressure. Our method for bonding connectors […]

Key Concepts in Plastic Assembly Stations

Advances in plastic assembly techniques have paved the way for innovative new products. However, the success of these processes heavily depends on operators working efficiently at their stations. Establishing an effective development, test, and production process requires systems that cater to both commercial interests and human physiology. Considerations for Deploying a Plastic Assembly Line in Your Company […]