Unlocking the Power of Thermal Assembly: A Comprehensive Guide

Thermal assembly, a cornerstone of modern manufacturing, encompasses a spectrum of techniques and specialized equipment tailored to meet diverse bonding needs. From the intricate components of automobiles, boasting over 30,000 parts, to the delicate specifications of medical devices subject to stringent FDA guidelines, the efficacy of thermal assembly can make or break the integrity of […]

Unlocking the Value of Heat Staking in Flexible Electronics Manufacturing

In the rapidly evolving world of electronics, flexible circuits and flexible electronics are gaining significant attention for their versatility and applications across industries like healthcare, automotive, consumer electronics, and aerospace. These circuits, characterized by their lightweight, thin, and bendable properties, enable innovative designs and functionalities that rigid printed circuit boards (PCBs) simply cannot offer. However, […]

Heat Sealing Equipment: Precision and Reliability with Thermal Press International

Thermal Press International (TPI) is a global leader in heat sealing solutions. Our advanced heat sealing presses empower product teams to create innovative, safe, and reliable seals for plastics, films, and foils. Regardless of the industry or application, TPI offers solutions that streamline the manufacturing process while ensuring precision and quality in heat-sealed products. Our […]

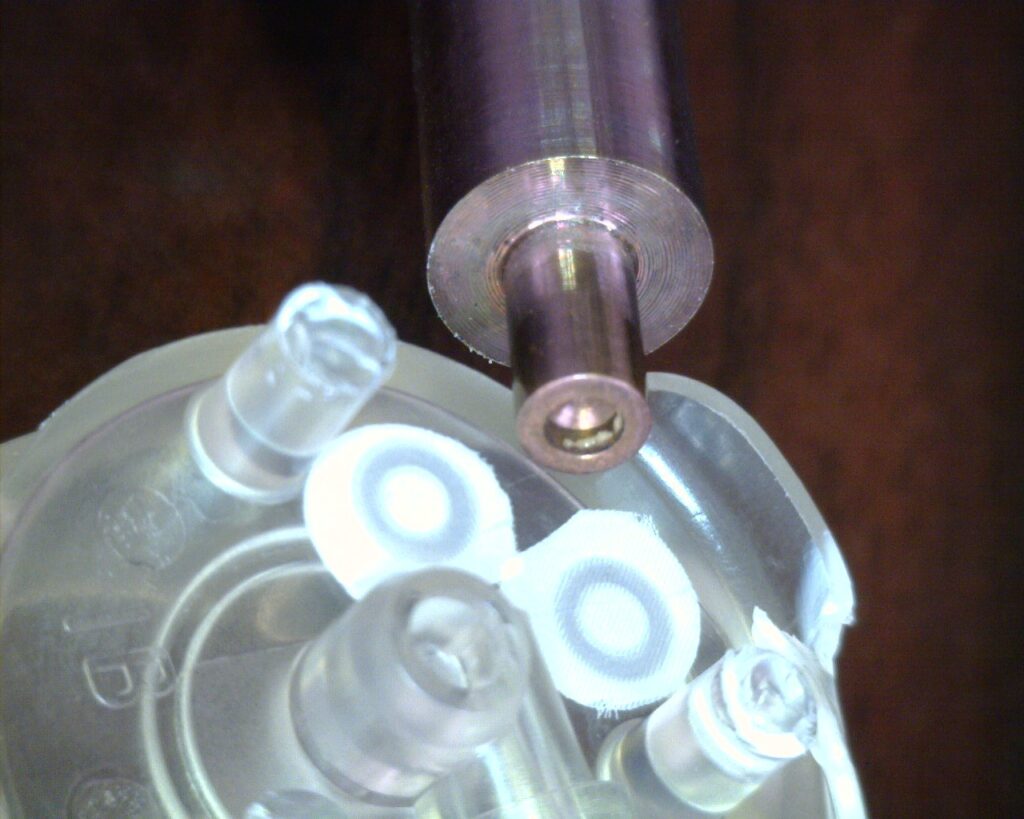

Revolutionizing Bioreactor Bag Sealing and Manufacturing with Thermal Press International

Since our inception in 1976, Thermal Press International (TPI) has been at the forefront of precision thermal and plastic assembly technologies, pioneering the development of thermal press machines. Today, we remain an industry leader in producing equipment for manufacturing high-quality bioreactor bags across various sectors. Why the Shift to Bioreactor Bags? Research conducted by BioPlan […]

Port Sealing: An Effective Heat Sealing Solution

Low-Cost Convenience For Prototyping Heat sealing is the process of sealing one thermoplastic to another similar thermoplastic using heat and pressure. The direct contact method of heat sealing utilizes a constantly heated die or sealing bar to apply heat to a specific contact area or path to seal or weld the thermoplastics together. Heat sealing […]

The Impact of Assembly Costs in Medical Device Development

According to Precedence Research, medical device contract manufacturing was valued at $72.89 billion worldwide in 2022 and is expected to reach $211.66 billion annually by 2032. As a result, companies are continuously scrutinizing development costs, seeking ways to enhance efficiency and reduce expenses. Underestimating Assembly Costs During the planning stages, it’s common to underestimate manufacturing and assembly […]

The Essential Role of Heat Sealing Foils and Film in Manufacturing Various Medical Diagnostics

In the rapidly advancing field of medical diagnostics, the demand for reliable, high-quality products is greater than ever. A critical process that underpins the manufacturing of these essential medical devices is continuous thermal heat sealing. This technique, which involves the application of heat and pressure to bond foils and films, ensures the integrity and functionality […]

The Benefits of Rosette-Shaped Heat Stake Posts and When to Use Them

Heat staking is a widely used technique for joining plastic components to non-plastic parts, such as metal or electronic elements, by softening and reforming a plastic post with heat and pressure. The shape of the heat stake post plays a critical role in the strength, durability, and precision of the bond. One of the more […]

The Value of Heat Staking in Piezoelectric Sounder Manufacturing for Medical Devices

In the world of medical devices, every component must perform with absolute reliability and precision. Among these components, piezoelectric sounders play a critical role by providing audible alerts and confirmation sounds, which are essential for both patient safety and user feedback. As medical devices continue to evolve, the assembly techniques for these sounders must also […]

Manufacturing Tips for Quality Plastic Assemblies

Quality plastic assemblies often rely on press fits to hold parts in perfect alignment. These bonded interference fits used in assembly connections provide consistent performance in a multitude of applications. The demand for press-fit assembly technology and heat sealing equipment shows that manufacturers are looking to near-shore manufacturing, to automate assembly processes, and to maintain […]