Thermal Press International (TPI) is a global leader in heat sealing solutions. Our advanced heat sealing presses empower product teams to create innovative, safe, and reliable seals for plastics, films, and foils. Regardless of the industry or application, TPI offers solutions that streamline the manufacturing process while ensuring precision and quality in heat-sealed products. Our expert engineers collaborate with your team to find the optimal solution, guaranteeing consistent and high-quality seals.

Heat Sealing Applications

When it comes to ensuring a high-quality connection of seal, TPI provides solutions that seamlessly integrate into your process. Our machines support clean substrate and heat seal connector (HSC) procedures, including:

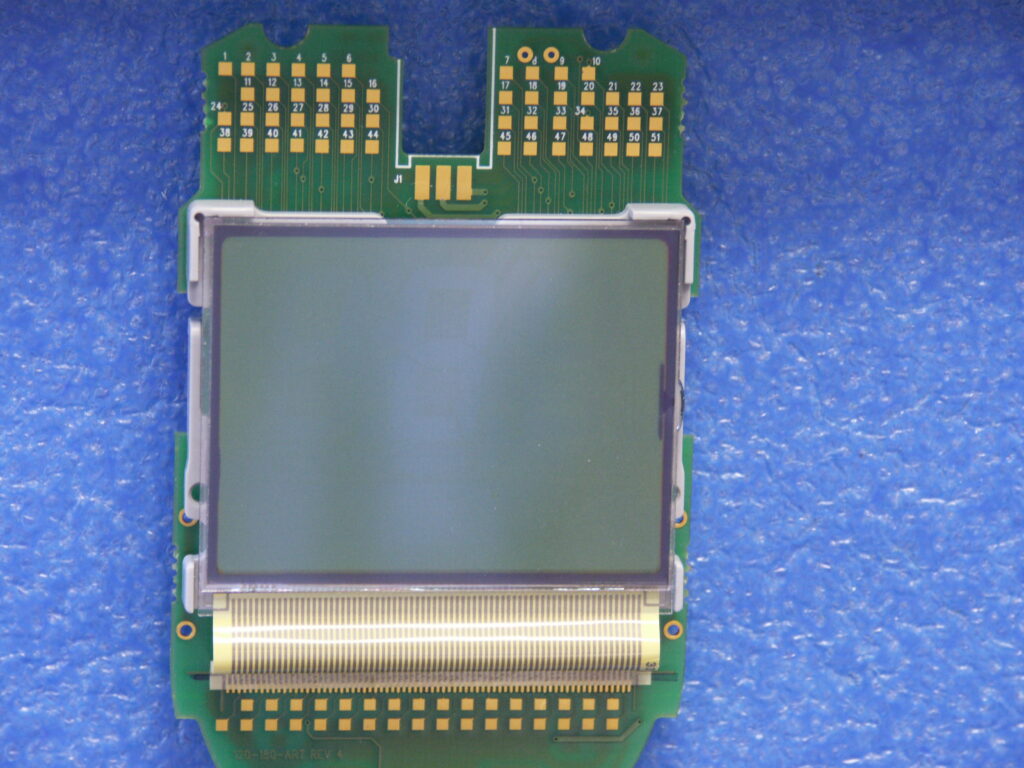

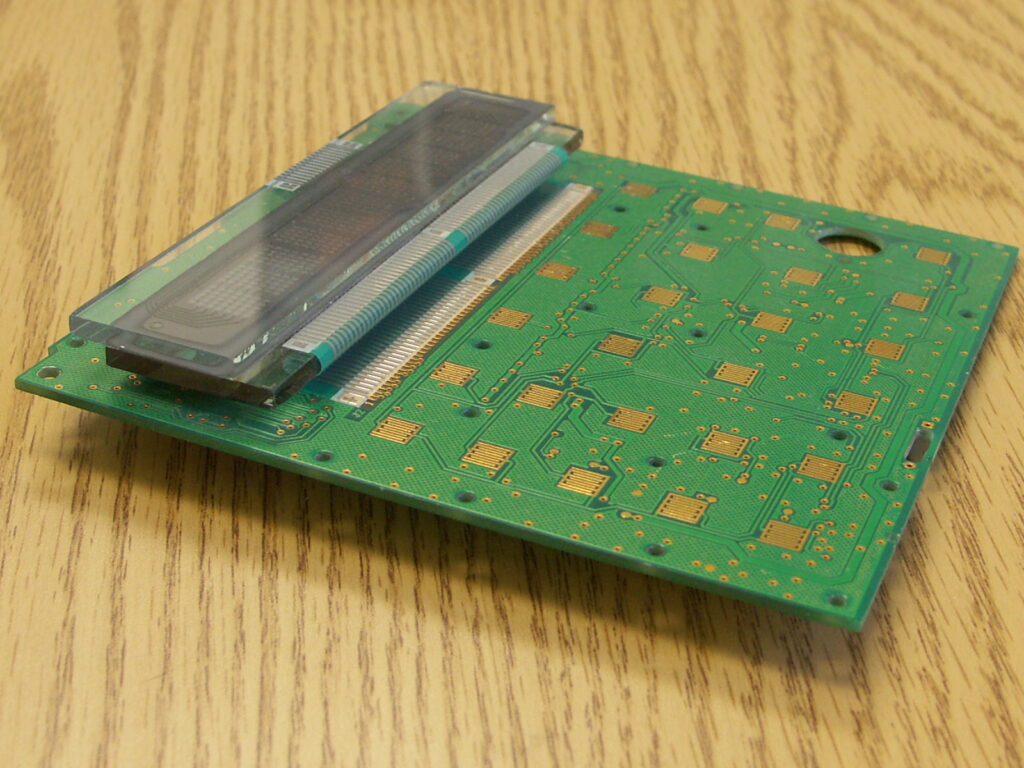

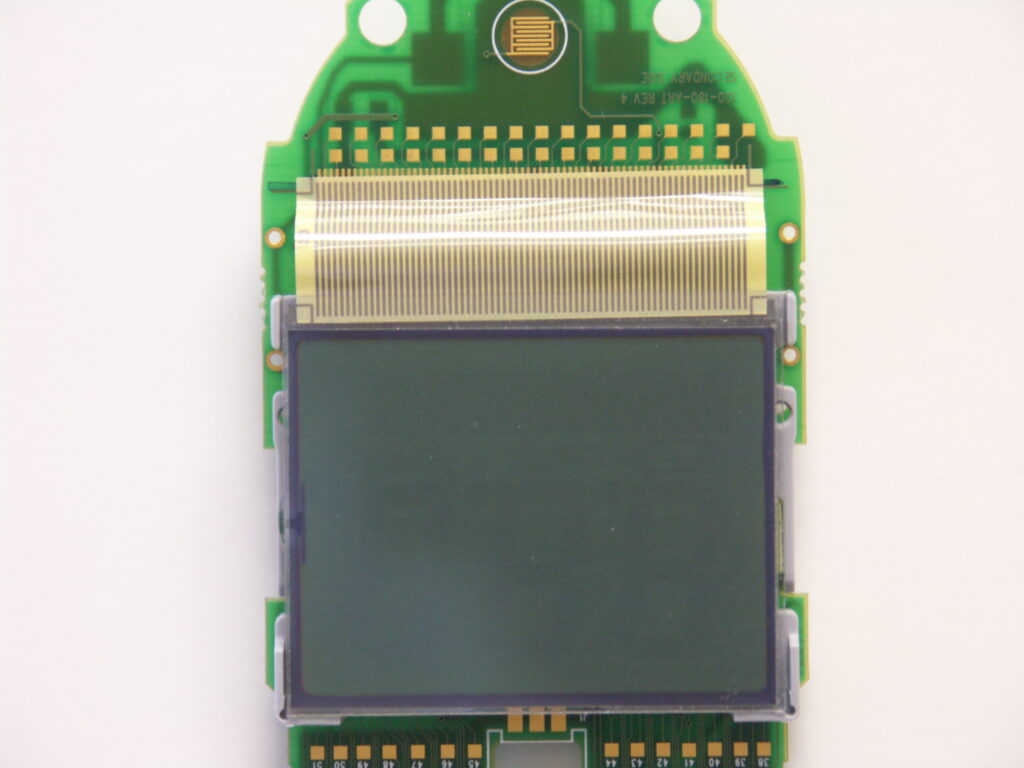

Bonding an HSC to Devices: Achieve precise bonding of HSCs to devices like liquid crystal displays (LCDs) or printed circuit boards (PCBs).

Preventing Inconsistencies: Eliminate issues such as inconsistent bond strength, misalignment, and continuity problems on individual traces.

Ensuring Consistency: Produce repeatable and consistent results by applying optimal pressure and temperature to the bonded area.

Maintaining Planarity: Maintain the planarity of bonding blades to HSCs and substrates for flawless seals.

Heat Sealing Solutions from Thermal Press International

TPI offers heat-sealing solutions for a wide range of products and devices, delivering superior bonding processes. Heat Sealing bonds one thermoplastic to another, forming a permanent seal. Ensuring a consistent, quality seal requires exact control over the temperature and pressure during the process.

Depending on your product type, you’ll need to verify that the final results comply with federal and international relations. Thermal welding of any two compounds necessitates a strict quality control process, requiring precise control at every stage of the manufacturing cycle.

A growing market of intelligent medical devices and automatic drug delivery systems relies on heat-sealing solutions. TPI provides a variety of platforms suitable for numerous industries. Unlike ultrasonic welding, our heat sealing process is not subject to degradation or debris, ensuring clean and reliable seals.

Suitable Applications for Heat Sealing Solutions

TPI’s heat sealing solutions are ideal for various applications, including:

Boat and Disc Port Seals: Essential in both the food and medical industries for secure seals.

Patch Welding of Adhesives: Supports wearable medical devices by ensuring durable adhesive bonds.

Film, Foil, and Filter Welding: Suitable for any type of film, foil, or filter sealing needs.

HSC and Anisotropic Conductive Film (ACF) Bonding: Ideal for fine pitch applications requiring precise bonding.

Device Sealing: Perfect for computer, telecommunication, and biomedical devices.

Thermal Press International Device Capabilities

Our devices enable high-quality manufacturing processes with precise controls and validation features. This is crucial in the medical and food industries for demonstrating compliance and ensuring the detection of any faulty seals.

For medical or food device assembly processes, if you need a quality seal that performs according to design specifications, TPI is your solution. Our equipment can also create elastomeric connectors positioned directly on top of PCB assemblies or LCDs. If your product or device requires a heat-sealing solution that depends on high precision and consistent processes, adopting a TPI machine in your assembly procedure is essential for maintaining product quality.

Creating Effective Heat Seals for Any Product with TPI

At TPI, precision and process control are our top priorities. Our platforms enable manufacturers to create consistent, quality bonds between any type of thermoplastic, suitable for various applications. With custom actuation, quick tooling changes, and exact temperature or pressure control, TPI’s heat sealing equipment ensures a repeatable, certifiable manufacturing process for any sophisticated assembly procedure.

Contact Us:

Contact Thermal Press International at (925) 454-9800 to speak with an engineer and explore how heat staking can optimize your manufacturing operations.