In the dynamic realm of automotive innovation, one aspect stands out: the evolution of LED technology. As a frontrunner in precision heat staking machinery, Thermal Press International (TPI) presents an array of solutions tailored to the intricate demands of LED taillight assemblies. Over the past two decades, the transformative strides in LED technology have reshaped consumer electronics and automotive lighting, ushering in an era of efficiency and aesthetic sophistication.

Gone are the days of bulky, power-hungry lighting systems. LEDs have emerged as the cornerstone of modern illumination, boasting unparalleled energy efficiency and versatility. From televisions to handheld devices, and from household appliances to automotive lighting, LEDs reign supreme. Within the automotive sector, in particular, LEDs have found their niche in taillights, instrument displays, and interior lighting, offering not only enhanced aesthetics but also addressing the pressing concerns of power consumption and wiring complexities.

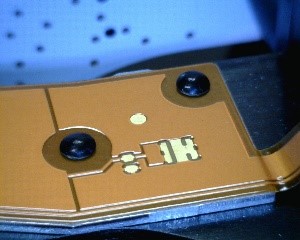

Central to the assembly of LED taillights is the technique of heat staking, a process perfected by TPI. Whether it’s metal clinch frames housing stamped LEDs or flexible circuit arrays adorned with surface-mounted LEDs, TPI’s solutions ensure seamless integration without compromising the integrity of the LEDs. This opens the floodgates of creativity for automotive designers, enabling the realization of avant-garde taillight designs that captivate the imagination and define the identity of new vehicle models year after year.

Key Features of TPI’s Customer LED Taillight Assembly Solutions:

- Tailored Precision: Customer tooling packages meticulously crafted to match the contours and surfaces of taillight plastics, ensuring a seamless fit and finish.

- Versatile Integration: Heat staking of thermoplastic posts across different planes and surfaces in a single machine cycle, guaranteeing precision without jeopardizing LED integrity.

- Precision Engineering: CNC machining of tooling components to mirror any contour of part shapes and features, facilitating optimal support, location, and clamping as required.

- Feature-Friendly Solutions: Family tooling packages available for assemblies necessitating operations on both top and bottom surfaces, streamlining production processes.

- Dual-Handed Efficiency: Multiple part handling capabilities cater to simultaneous production requirements for both right-hand and left-hand assemblies, maximizing efficiency.

- Heightened Adaptability: Taillight heat staking processes adeptly accommodate multiple thermoplastic post heights and diameters, ensuring compatibility with diverse design specifications.

- Tailor-Made Profiles: Customizable heat stake head profiles, whether standard or made-to-order, crafted during the heat staking process to meet exacting requirements.

- Precision Assurance: Interchangeable clamping plates of uncompromising precision, a hallmark feature of TPI’s taillight assembly solutions.

In the ever-evolving landscape of automotive lighting, TPI stands as a beacon of innovation and precision. With their customized LED taillight assembly solutions, they empower automotive manufacturers to push the boundaries of design while ensuring uncompromising quality and efficiency. Revolutionize your automotive lighting experience with TPI’s precision-led solutions, where innovation meets perfection.

Contact Us: Contact Thermal Press International at (925) 454-9800 to speak with an engineer and explore how heat staking can optimize your manufacturing operations.